ARNOLD AIR FORCE BASE, Tenn. — A multiyear, multimillion dollar effort has led to the successful reactivation of von Kármán Gas Dynamics Facility (VKF) Wind Tunnel D at Arnold Air Force Base, officially ending a period of dormancy for the tunnel that exceeded its original run.

Tunnel D is operated, managed and scheduled by members of the Air Force Research Laboratory High Speed Experimentation Branch at Arnold. The facility is viewed as a cost-effective way to perform diagnostic development as well as supersonic and hypersonic flow phenomenology research.

The tunnel was authorized for routine research operations on Feb. 20. During the seven subsequent weeks, AFRL researchers, employing a variety of diagnostic techniques, completed several test entries over more than 70 supersonic wind tunnel runs. Through this period, the researchers were able to characterize the facility’s freestream flow quality, evaluate turbulent corner flows and identify fluid-structure interactions.

Originally built as a small-scale demonstrator for VKF Wind Tunnel A, Tunnel D can generate flows ranging from Mach 1.5 to Mach 5 for up to five minutes at a time. Shorter runs, typically ranging from 30 to 90 seconds, will be common for normal research operations, allowing several runs per day. The downtime between runs can be as short as 15 to 30 minutes.

Tunnel D is a pressure-vacuum blowdown wind tunnel, meaning it uses a high-pressure air source and a vacuum sphere to generate the needed pressure ratio across its nozzle. As the air flows through the nozzle throat, it accelerates through Mach 1 to the test Mach Number in the tunnel’s 12-inch by 12-inch test section. This test Mach Number can be varied between tests via manual adjustment of the flexible-wall nozzle.

“Because the tunnel uses only a very tiny fraction of the base’s vast high-pressure air utility, and because AFRL operates its own vacuum system, Tunnel D is able to run largely independently of other activity at Arnold,” said Tunnel D Lead Engineer Dr. Jerrod Hofferth.

Unlike other VKF continuous-flow wind tunnels, Tunnel D is operated intermittently. Branch Chief Glenn Liston said that this operating mode, coupled with the tunnel’s brief downtime between runs, makes it ideal for research operations. Operators have the option of waiting a day or two while evaluating test results without impacting operations costs.

“Tunnel D also achieves different test conditions than AFRL’s other supersonic and hypersonic wind tunnels,” Liston said. “It complements the AFRL’s three high Reynolds Number Mach 3 and Mach 6 wind tunnels at Wright-Patterson Air Force Base. Taken together, the four wind tunnels provide the Air Force with a wide range of operating conditions for the Air Force’s hypersonic research.”

Tunnel D is set to play a significant role in supporting the Air Force’s hypersonic research portfolio. It will also be used as a diagnostics testbed and calibration platform. The tunnel can be used to verify test methods and performance characteristics prior to large-scale testing in a continuous-flow wind tunnel.

The upcoming research and test operations schedule for Tunnel D is expected to be very busy.

“We have only been operational for a few months and have just begun advertising our capabilities, and already the rest of 2019 is completely booked with both in-house and external customers, and many test campaigns for 2020 are in the planning stages,” said tunnel Operations Officer Maj. Mark Birdwell. “Long term, the tunnel will operate a balance of projects designed to further high-speed knowledge for an AFRL-centric mission, with AEDC-partnered projects designed to bridge the gap between science and technology on the AFRL side and test and evaluation on the AEDC side. These projects will span the spectrum of AFRL in-house, AEDC-sponsored, government-sponsored Small Business Innovation Research programs, and other customers that can contribute to the mission.”

The majority of the planned research in Tunnel D will focus on aerodynamic phenomena and its impact on high-speed vehicle subsystems. This includes relatively simple test articles that incorporate fundamental shapes up to complex subscale flight hardware.

“While some potential users are interested in test and evaluation metrics such as forces and moments, a majority of the tunnel campaigns will leverage AFRL expertise in research-grade instrumentation,” said Technical Advisor Dr. Scott Peltier. “Non-intrusive and laser-based diagnostics form a central part of the AFRL measurement capability, and ongoing in-house and contracted efforts are underway to mature these measurements for use in large-scale facilities.”

Peltier said a key advantage of Tunnel D is its flexibility.

“The branch research portfolio covers fundamental research through applied testing, so we need similar flexibility in the types of test articles we can use,” he said. “Our basic science efforts can use fundamental geometries such as flat plates, or even the walls and corners of the wind tunnel test section itself, for investigations of boundary layer evolution. As we investigate vehicle subsystems and built-up structures, we’ll be mounting increasingly complex test articles in the wind tunnel, such as high-speed inlets and panels representative of flight-weight vehicle skins. These can be mounted in the tunnel freestream or integrated into one of the test section sidewalls.

“Each mounting location provides different constraints in terms of optical access – for non-intrusive diagnostics – and instrumentation. One of our earliest contracted efforts will design a rigid model mount for the facility, and we will be expanding upon that capability over the next 12 to 24 months.”

In September 1953, Tunnel D hosted the first paid customer test on AEDC grounds – the Hughes E-1 Falcon, an air-to-air missile. Over the next 24 years, it hosted a variety of tests and research projects.

“Much of what we take for granted today in the operation of supersonic wind tunnels was, in no small part, learned through extensive parametric testing at Tunnel D in the ‘60s and ‘70s,” Hofferth said. “Some examples include what is now standard guidance on starting and unstarting pressure ratios, test article blockage area ratios and loads, and the effect of wind tunnel freestream noise on boundary-layer transition.”

The tunnel ceased to operate in 1977, ending 24 years of activity. The facility remained dormant for the next four decades. Over the years, Building 607, where Tunnel D is housed, and the tunnel itself fell into disrepair.

“Although the building was periodically used as a temporary workspace for craft labor crews, it had not been maintained to where it would be a viable facility for research and test operations. Simply put, it looked like your classic abandoned warehouse,” said Tunnel D Program Manager Dan Ogg. “Almost $1 million in AFRL funding was awarded to help revitalize and modernize Building 607 into what is now a well-equipped lab space, with a new roof, fresh coats of paint, adequate lighting, a modern control room, and a number of engineering workspaces suitable for laser diagnostics.”

The AFRL-funded renovation project began in 2016. The remaining components of the tunnel were disassembled, inspected and refurbished. Most of the supporting subsystems, such as isolation valves, control valves, the heater, hydraulics, high-pressure air connections, controls and data systems, were completely replaced.

“Over the course of two years and $4.5 million, and countless labor hours from both AFRL and AEDC, the reactivation returned a valuable research and test asset to its former glory,” Ogg said.

The February operations authorization of Tunnel D followed a series of subsystem checkouts and shakedown runs that occurred over the preceding months. The first on-air operations at the renovated facility were conducted in February 2018, and the upstream systems checkouts, conducted at a subsonic flow, would continue through September 2018.

Supersonic checkouts of Tunnel D at Mach 4 began in November 2018 and continued through the end of January. After a successful research series at Mach 4 during February through April, the first operations at Mach 5 then occurred earlier this month.

Tunnel D is unique in that AEDC owns all of the facilities, including the wind tunnel itself, but AEDC has agreed to grant executing authority of the facility to AFRL. Birdwell said this has required a number of complex partnerships and agreements between AFRL and AEDC, encompassing safety, security, maintenance, logistics and operations.

Birdwell, while crediting the diligence of those involved, said operations have been “extremely smooth.” He said the AFRL participates in all aspects of AEDC planning and operations in the same capacity as the other Combined Test Forces at Arnold and coordinates the Tunnel D requirements and scheduling through the normal AEDC processes.

“Smooth operations and planning are assisted by the fact that our tunnel was designed to have very low operational requirements, so we barely impact the larger facilities on base even when running at our peak,” Birdwell said. “For instance, our High Pressure Air usage is often noted to be no more than a leak on the overall system, as we would require less than 5 percent of the total base capabilities to run an entire day’s operations at our max flow rate. These low requirements allow us to run at the same time as the other operations on base, providing for much smoother scheduling and coordinating on both sides.”

Ogg said contractors across Arnold played a key role in the Tunnel D reactivation efforts. Although AFRL funded and managed the effort, Ogg said on-base contractors, including engineers and craft personnel, aided in the design, procurement, fabrication and installation of various subsystems for Tunnel D.

“Much of the contracted team remains involved to some extent during our day-to-day operations,” he said. “Much of our supporting subsystems, such as hydraulics and vacuum, require regular maintenance and upkeep, while we also look to many on-base engineers to help implement robust upgrades as we learn how to more efficiently operate the tunnel. Because the facility was designed to be operated with a very small number of personnel, most of the day-to-day test campaigns are executed by AFRL personnel. However, we still heavily rely on the contracted support for ensuring the tunnel is operating nominally.”

Hofferth expressed his appreciation for those who worked to make the successful reactivation of Tunnel D possible.

“AFRL would like to thank the AEDC family for the warm welcome and excellent support that our group has received since our stand-up and throughout the effort to reactivate and operate Tunnel D,” Hofferth said.

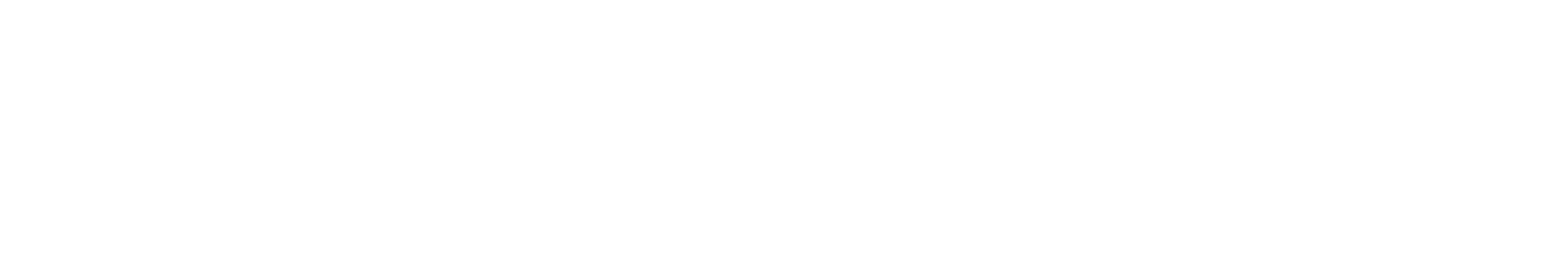

The von Kármán Gas Dynamics Facility Wind Tunnel D test facility operated by the Air Force Research Laboratory High Speed Experimentation Branch at Arnold Air Force Base, seen here June 5, was reactivated earlier this year. (U.S. Air Force photo by Jill Pickett)

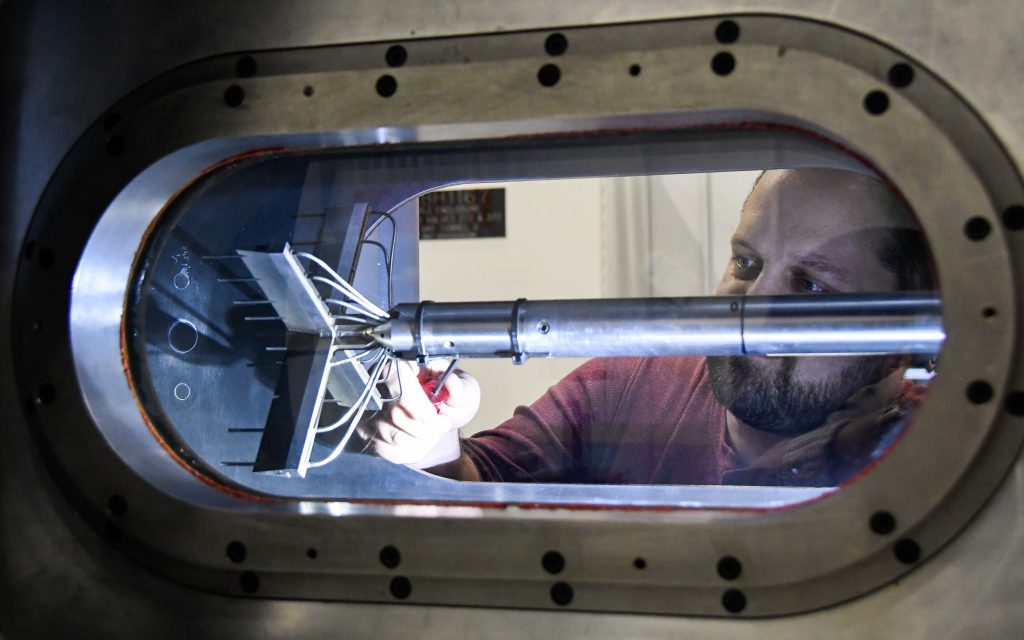

Dr. Jerrod Hofferth, von Kármán Gas Dynamics Facility Wind Tunnel D lead engineer, works on a freestream characterization rake, used to determine Mach Number Uniformity, positioned in the Tunnel D test cell June 5 at Arnold Air Force Base. The tunnel was reactivated earlier this year and is operated by the Air Force Research Laboratory High Speed Experimentation Branch. (U.S. Air Force photo by Jill Pickett)