AFRL extends capability for testing solid rocket motors with new equipment

EDWARDS AIR FORCE BASE, Calif. (AFRL) – The Air Force Research Laboratory’s Rocket Propulsion Division has a new capability, a Split-Hopkinson Pressure Bar system, also known as a Kolsky bar, that measures stress at high strain rates and helps analyze material behavior under severe conditions.

“This system will give AFRL a new and unprecedented capability to test and gather data from any solid propellant we can manufacture,” said Dr. Timothy Miller, senior materials research engineer within AFRL’s Propellant Branch. “This new equipment capability will continue to propel AFRL into the future,” he said.

Installed in AFRL’s on-site chemistry lab, the system tests solid propellant at strain rates that correspond to threats from bullet impact, fragment impact and sympathetic detonations. The latter occur when unwanted detonation of a missile issues a shock wave that initiates detonation in a nearby missile.

“AFRL plans to use the system to test both propellant and space-bound materials at high-strain rates so that structural models can be developed that will predict behavior, especially failure, in real-world conditions,” said Miller.

Ultimately, these models will aid in designing improved rocket motors and satellites. This new capability will also help AFRL to investigate other occurrences such as space debris impact, which can disable satellites, and in some cases, can compromise structures and render them useless.

Miller explained how “every solid rocket motor tested has the potential for defects that cannot be seen during manufacturing, and even in the absence of defects, can be susceptible to damage due to external events.”

“Data from high strain rate tests is key to preventing [unintentional damage] and AFRL will use this system to quantify material properties related to all rocket motors, including those made with advanced manufacturing processes such as Resodyn mixing and additive manufacturing,” he said.

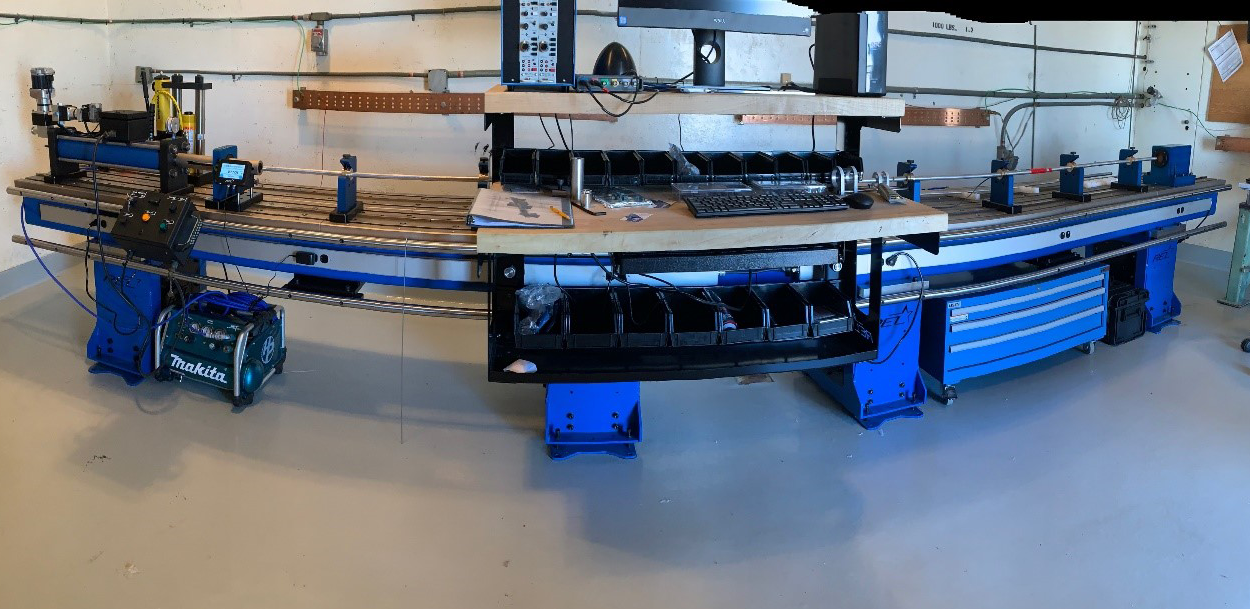

AFRL’s new equipment, a Split-Hopkinson Pressure Bar system, measures stress at high strain rates and helps analyze material behavior under severe conditions. Engineers from AFRL’s Rocket Propulsion Division at Edwards Air Force Base, California will use the system to test and gather data from solid propellants and space-bound materials. (U.S. Air Force photo/Joy Alich)

AFRL’s new equipment, a Split-Hopkinson Pressure Bar system, measures stress at high strain rates and helps analyze material behavior under severe conditions. Engineers from AFRL’s Rocket Propulsion Division at Edwards Air Force Base, California will use the system to test and gather data from solid propellants and space-bound materials. (U.S. Air Force photo/Joy Alich)