AFRL showcases workforce talent, ingenuity, passion at 2023 Inspire event

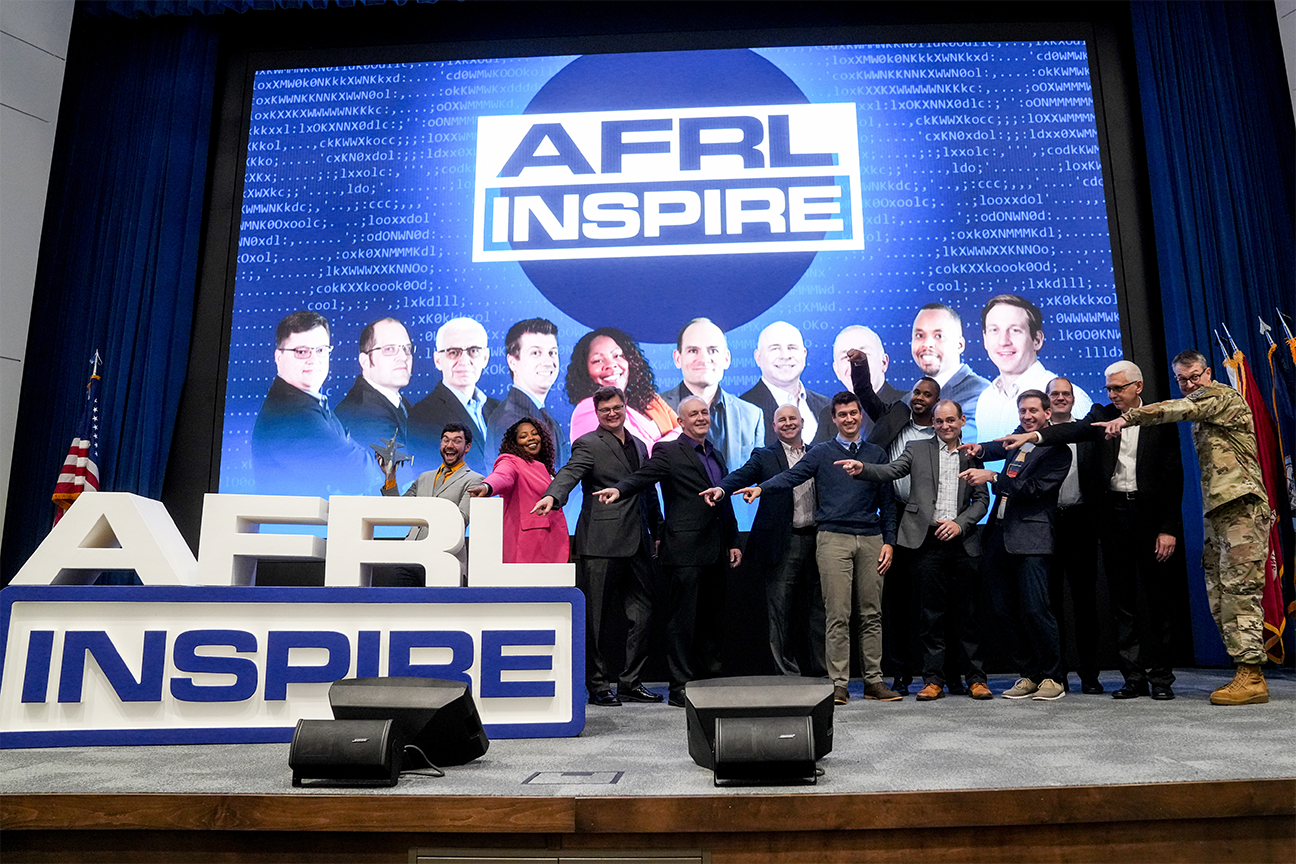

WRIGHT-PATTERSON AIR FORCE BASE, Ohio (AFRL) – The Air Force Research Laboratory, or AFRL, showcased a sampling of some of its best and brightest minds at the seventh iteration of its recurring AFRL Inspire event, held at the Air Force Institute of Technology’s Kenney Hall Oct. 26, 2023. This year’s program featured 10 distinguished speakers from across the AFRL enterprise who delivered a series of nine live TEDx-style talks designed to inspire listeners and highlight the passion, innovation and pioneering spirit of AFRL’s science and technology, or S&T, workforce.

Air Force Research Laboratory, or AFRL, Commander Brig. Gen. Scott Cain delivers his opening remarks to an in-person audience at the 2023 AFRL Inspire event at the Air Force Institute of Technology’s Kenney Hall Oct. 26, 2023. (U.S. Air Force photo / Cherie Cullen)

The 2023 roster of AFRL Inspire speakers were unified in driving home the message “One AFRL Team, One Fight.” The event was the first Inspire to occur under AFRL Commander Brig. Gen. Scott Cain’s leadership, as well as the first to take place in front of a live and in-person audience since the coronavirus pandemic. Virtual attendees had the option to view the three-hour program via livestream on AFRL’s YouTube channel. A recording of AFRL Inspire 2023 livestream is available on AFRL’s YouTube channel here.

Air Force Research Laboratory, or AFRL, Commander Brig. Gen. Scott Cain, far right, and AFRL Public Affairs Specialist and event host Kenneth McNulty, far left, stand onstage with the 2023 AFRL Inspire speaker lineup at the Air Force Institute of Technology’s Kenney Hall Oct. 26, 2023. (U.S. Air Force photo / Cherie Cullen)

Following opening remarks by event host and emcee, AFRL Public Affairs Specialist Kenneth McNulty, Cain took the stage to welcome attendees and to offer a poignant example of one of his own past sources of inspiration: a former friend, colleague and fellow Department of the Air Force pilot who pioneered significant advancements in fighter aircraft technology for the Air Force in the early 1990s. The pilot’s efforts translated to future iterations of aircraft that were safer to fly, enabling many of Cain’s pilot friends to return home safely after successfully executing their missions to Afghanistan following the events of Sept. 11, 2001.

Air Force Research Laboratory, or AFRL, Public Affairs Specialist Kenneth McNulty shows off a model F-16 fighter aircraft from onstage at the 2023 AFRL Inspire event at the Air Force Institute of Technology’s Kenney Hall, Oct. 26, 2023. (U.S. Air Force photo / Cherie Cullen)

“I’m inspired by what Bill did that changed the future, that affected my life so deeply,” Cain said. “This is the kind of stuff we do and have done since our inception at AFRL, before it was even named AFRL … It’s the people who make that happen.”

Cain credited AFRL “thought leaders” like those listed on the day’s speaker lineup as individuals who will affect future positive change for the Air Force.

“My hope is that these pioneers — who are often quiet pioneers, who are going to affect and change the future in the next 20 years — are inspiring to you,” Cain said. “Really, what I hope is that all the people of AFRL are as inspiring to you as they are to me.”

Following Cain’s remarks, McNulty returned to the stage to introduce the day’s speaker lineup, offering bits of comedic wisdom between speeches.

The diverse group of Inspire 2023 presenters offered a deeper look into the talent and ingenuity embedded within AFRL’s S&T labor force, using humor and emotion to highlight some of the latest research and development efforts currently underway in the lab.

Dr. Dan Berrigan: “Tackle the toil”

Berrigan, worldwide digital collaboration lead with AFRL’s Digital Capabilities Directorate, kicked off the show with the story of how, in the spring of 2020, he teamed with mathematician and fellow AFRL colleague Dr. Lauren Ferguson to scale a preexisting Google Workspace environment — then utilized by only a select few — to pilot a program that would make the Google Cloud platform widely available to all AFRL users. The switch to Google from preexisting legacy tools enabled the AFRL workforce to conserve precious time, energy and toil throughout their workdays, increase productivity and remain apace with peer adversaries.

“Toil is the manual mundane — devoid of any enduring-value task — that takes us away from what we really care about,” Berrigan said. “It was in this crucible of urgency that the AFRL Google Cloud pilot was born.”

Roughly three-fifths of AFRL’s workforce, or approximately 6,500 people, are scientists and engineers, Berrigan said. Collectively, Berrigan estimated, those individuals have approximately 260,000 hours each week with which to accomplish their mission. However, many of those hours are wasted battling with outdated computer technology that hampers productivity. Berrigan and Ferguson were looking to multiply productivity and scale, resulting in faster outcomes, Berrigan said.

In the face of ongoing coronavirus pandemic challenges, Berrigan and Ferguson worked to increase the total number of AFRL Google Workspace users from roughly 10 in 2019 to over 3,000 in 2023.

As a result of this experience, Berrigan said, he realized three important things.

“[A problem] isn’t fixed until it’s fixed for everyone,” Berrigan said. “[Secondly], it’s not just who we fund, but it’s who we inspire to work on our problems with us . . . What we documented and shared can be leveraged across the [entire] Department of Defense.”

Lastly, Berrigan said, he learned that return on investment does not manifest “simply in dollars.”

“It’s in influence, in seeing a colleague or employee realize their full potential,” Berrigan said. “And it’s in time.”

In closing, Berrigan noted that, at the end of the day, time is the only resource that AFRL shares equally with its adversaries.

“And in order to stay one step ahead, we have to tackle the toil,” Berrigan said.

Dr. Dan Berrigan, worldwide digital collaboration lead with the Air Force Research Laboratory, or AFRL’s, Digital Capabilities Directorate, kicked off the 2023 AFRL Inspire event at the Air Force Institute of Technology’s Kenney Hall, Oct. 26, 2023, with his speech “Tackle the Toil.” (U.S. Air Force photo / Cherie Cullen)

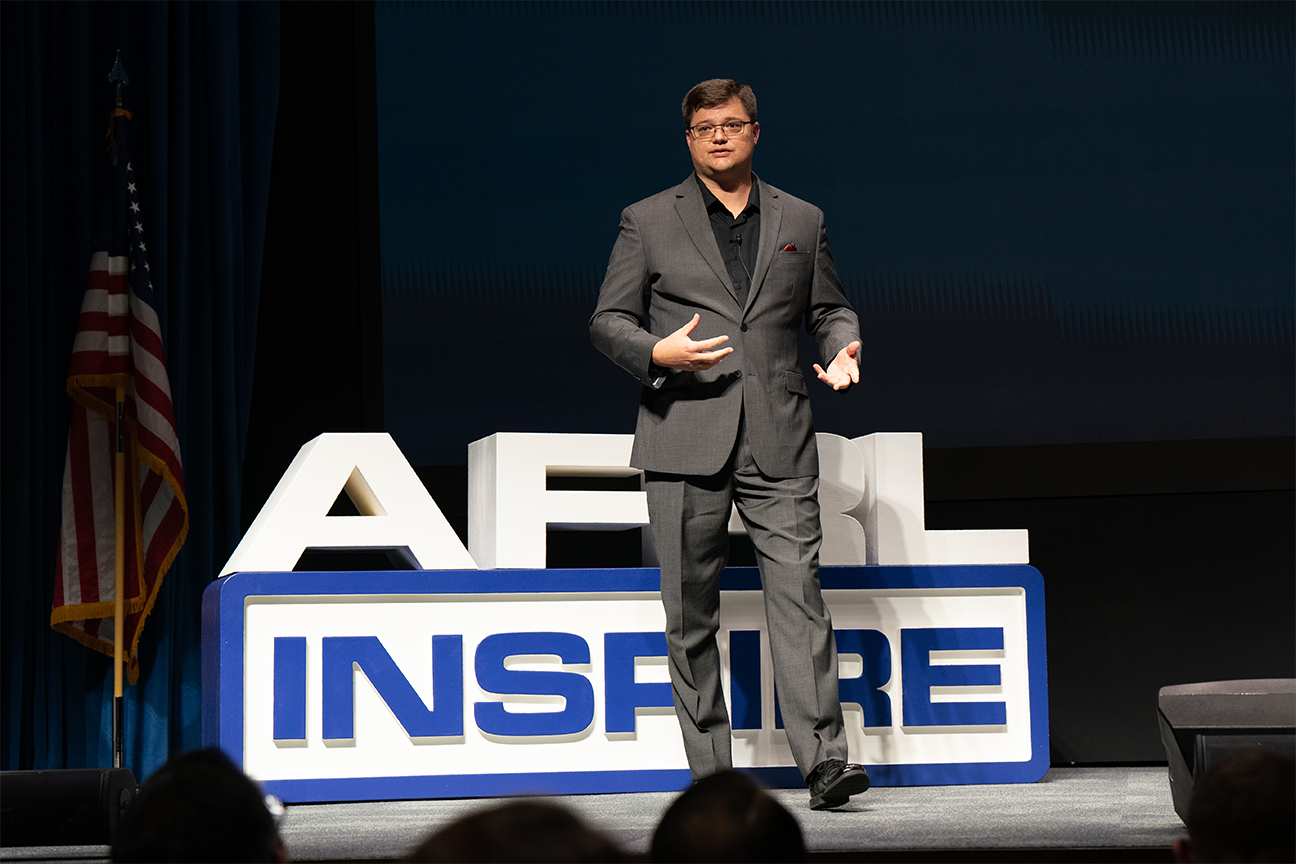

Matt Duquette: “Autonomous aircraft: A partnership of human and machine”

As humans grow increasingly worried about AI rendering them obsolete, it is important to recognize that the partnership between humans and machines is a source of strength, argued Duquette, an aerospace engineer based in AFRL’s Integrated Capabilities Directorate. The theory of “Humans Are Best At”-“Machines Are Best At”, or HABA-MABA, posits that humans are better at certain tasks while machines excel at others, and in learning to work together, true progress can be achieved, Duquette said.

Duquette, who has spent his AFRL career building autonomy for aircraft, first acknowledged why humans are afraid of machines.

“One of the most human of traits, the ability to create art, is now increasingly being done by AI,” Duquette said. “What’s scarier than AI questioning our humanity? AI making life-and-death decisions. Fear of the drone, an AI killing machine — the image of robots with lifeless cameras, designating targets, launching weapons — is the stuff of Sci-Fi nightmares. Combining the power of drones with the complexity of AI is something any reasonable person would fear.”

Still, Duquette said, he wished to present another perspective: that AI plays an important role in making humans better decision-makers and safer operators of machines.

“AI isn’t just a technology that makes machines better; it makes people better and the partnership of the two is getting stronger every year,” Duquette said. “Modern commercial planes automate the many tasks that used to require a third roommate. Without AI, we wouldn’t be able to fly with just two pilots. AI makes flying safer and more efficient.”

In terms of autonomous aircraft, machines are best at maintaining speed and direction, Duquette said, while humans are best at understanding the why: purpose and priority.

“It’s the partnership of the two — humans and machines — that yields the best result,” Duquette argued. “HABA-MABA is how we survive and dominate in modern warfare.”

Ultimately, trust is how one builds a partnership between a machine and its human operator, Duquette said.

“We move from automation to autonomy by building trust,” Duquette said. “We can remove the human from harm’s way … if we trust the machines to manage themselves. The mission will still belong to the person, but only if the mundane can belong to the machine.”

Duquette said as the U.S. military moves from remotely piloted to remotely commanded teams of airplanes, he envisions a future in which teams of aircraft manage themselves through the mission, executing a high-level intent from a human operator.

“What we really fear is agency,” Duquette said. “But fear of AI can cause us to miss opportunities to truly revolutionize our operations. We don’t give our airplanes agency to do whatever they want; we give them autonomy to manage the mundane.”

The right AI ensures humans will always be part of the solution, Duquette assured the audience.

Matt Duquette, an aerospace engineer based in the Air Force Research Laboratory, or AFRL’s, Integrated Capabilities Directorate, offers remarks on the future of artificial intelligence and autonomous aircraft in his speech “Autonomous Aircraft: A Partnership of Human and Machine” at the 2023 AFRL Inspire event at the Air Force Institute of Technology’s Kenney Hall, Oct. 26, 2023. (U.S. Air Force photo / Cherie Cullen)

Dr. Craig Przybyla: “Doors are made to open”

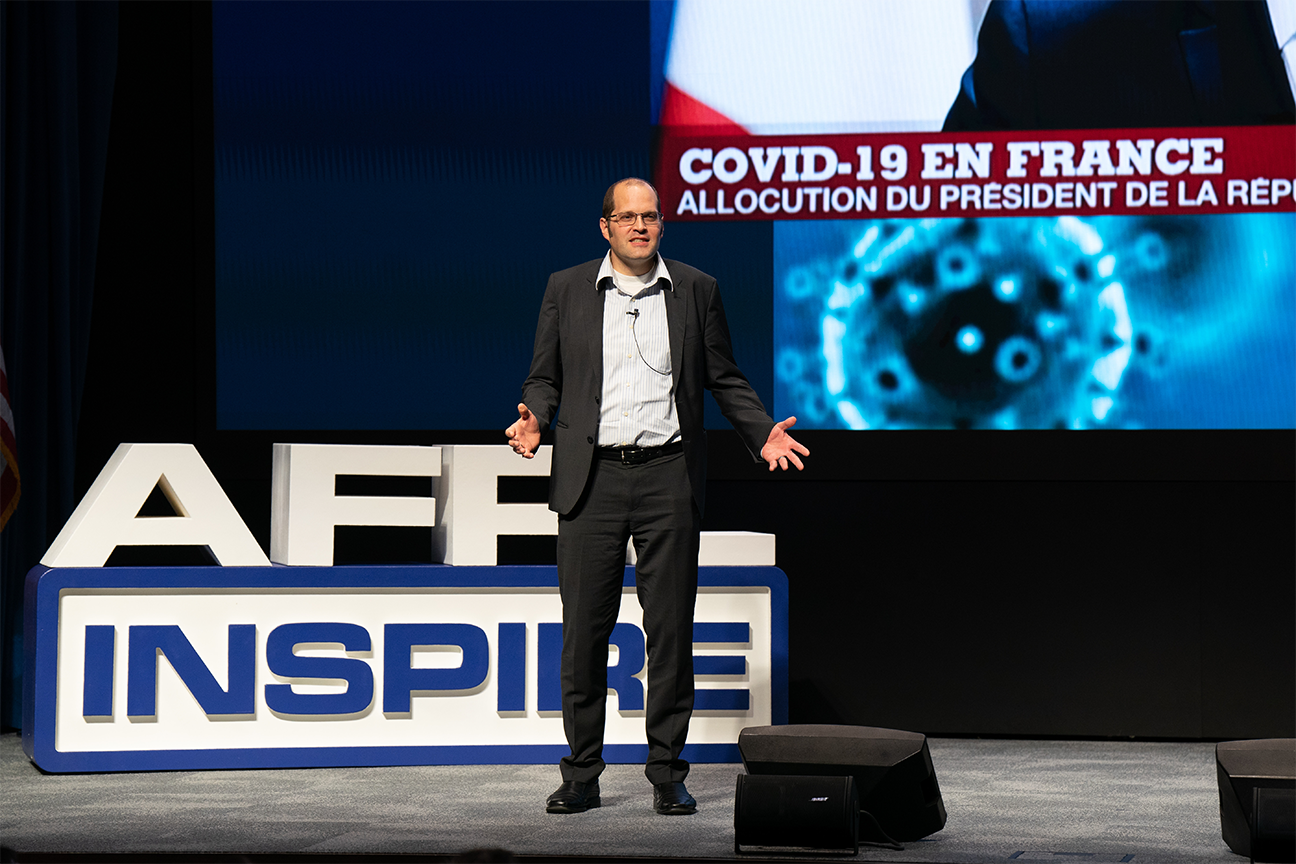

Przybyla, a principal materials engineer and team lead based in AFRL’s Materials and Manufacturing Directorate, framed his experience living in Paris, France, with his wife and seven children at the height of the coronavirus pandemic lockdowns in the spring of 2020 as one that taught him how to push through the metaphorical doors that sometimes blocked his way, not just in work but also in life.

“Sometimes, those doors are locked, and we have to push through them,” Przybyla said.

In 2018, Przybyla applied for a DAF program called the Engineering and Scientist Exchange Program, or ESEP, that enables scientists and engineers to work for two years while embedded in the research lab of an allied nation. Przybyla was selected to go to Paris and traveled there with wife and children. While at first the family encountered significant obstacles or blocked doors — his wife’s purse, which contained her passport and cell phone, was stolen; Przybyla struggled to learn how to drive a large family van on narrow Parisian streets and at one point accidentally sideswiped another car; French transportation workers went on strike, making it impossible to drive to work — “we pushed forward, we adapted,” Przybyla said.

Then, the coronavirus pandemic erupted in Europe and France locked down. The Przybyla family were apartment-bound 23 hours a day and forbidden to travel any further than 1 kilometer from their home.

Still, Przybyla said, the family continued to adapt, creating a new family schedule that would allow them to focus on online schooling and work. They came up with creative ways to cope with their new normal, and hosted egg-drop competitions, Nerf gun games with neighbors, photography and art competitions and board game marathons. Przybyla’s spouse even gave birth to the family’s seventh child in an inflatable birth pool, in a bedroom of their temporary Parisian home.

Through it all, Przybyla said, he and his family adapted to their new, challenging circumstances, continually trying closed doors until they found ones that opened. Eventually, Przybyla, a composites researcher, learned to apply this strategy to not only his personal life, but also his work.

“As my family learned to adapt to living through COVID-19 lockdowns, I also had to learn how to adapt to teleworking for most of the remaining 18 months of my exchange program,” Przybyla said.

Using innovative approaches to problem-solving, some of which were inspired by open-source tools that he located online, Przybyla, in partnership with his French collaborators, was able to resolve a very specific set of complex challenges unique to his composite research when all other methods he had previously tried had failed.

Innovation in life and research is dependent upon the key principles of iterative adaptation and strategic partnership, Przybyla said. In other words: individuals should observe a changing situation, orient themselves within it, decide on a plan of action, and then act.

By employing this iterative loop and partnering with others, individuals can be more successful in the face of evolving challenges, Przybyla said.

“Our neighbors were essential to our survival during COVID just as much as me working with my French collaborators was essential to solving a difficult materials characterization problem with no easy data,” Przybyla said.

In closing, Przybyla urged his audience not to allow closed doors to stop them.

“Open them,” Przybyla said. “Step into the dark passages and move forward. As you encounter dead ends, don’t be afraid to iterate and try new doors. Along the way you will be more successful if you partner with others. They will have found keys to some of the locked doors or know which doors are most promising.”

Dr. Craig Przybyla, a principal materials engineer and team lead based in the Air Force Research Laboratory, or AFRL’s, Materials and Manufacturing Directorate, shares his experience living in Paris, France, with his wife and seven children at the height of the coronavirus pandemic lockdowns in his speech “Doors Were Made to Open” at the 2023 AFRL Inspire event at the Air Force Institute of Technology’s Kenney Hall, Oct. 26, 2023. (U.S. Air Force photo / Cherie Cullen)

Dr. Alex Alaniz: “Helen Keller, ChatGPT and Einstein”

Alaniz, a principal physicist and technical adviser based in AFRL’s Directed Energy Directorate, discovered throughout his career that his true passion is understanding intelligence. In his talk, Alaniz explained the thought process he underwent while developing an Albert Einstein avatar as part of his recent quest to further his theory of intelligence.

“We go through life connecting bits of information,” Alaniz said.

Helen Keller learned to relate concepts to make sense of the world around her, Alaniz explained in his opening remarks. Even though Keller was deaf and blind, she learned the meaning of the word “water” by associating the sensation of cool liquid with the word that Annie Sullivan drew on her hand.

Artificial General Intelligence, or AGI, is a hypothetical type of intelligent agent that can learn to accomplish tasks through a similar process: by connecting pieces of information together to form a complex framework of knowledge.

AGI technologies are at everyone’s fingertips, Alaniz said.

“To understand the promises and threats of AGI, we need a theory of general intelligence,” Alaniz said.

Alaniz approached this theory in his garage lab while thinking of Helen Keller and how she became literate and verbal by associating concepts, which inspired him to build an avatar of Albert Einstein that, with the help of a ChatGPT bot, can communicate in an approximation of Einstein’s voice, answering questions and holding conversations.

Alaniz designed his Einstein avatar by creating a connection process that enabled it to relate concepts using embedded text files that build upon one another to collect and relay information. The goal, Alaniz said, was to create an avatar that speaks the truth.

When used alone, ChatGPT “hallucinates,” Alaniz noted.

“It drifts off, invents false facts,” Alaniz said. “Einstein Avatar can’t, because it’s based on facts.”

In closing, Alaniz described future plans to develop his Einstein avatar further and to equip it with more complex knowledge using a story narration strategy.

Humans need not fear that AGI will surpass human capabilities — at least not right now, Alaniz noted.

“We shouldn’t be afraid of AGI until it can create spiderweb frameworks as rich or richer than ourselves,” Alaniz said.

In closing, Alaniz acknowledged the fact that many people ask him why he chooses to research a topic like this, delivering a line he attributed to Sam Seaborn’s character on an episode of the television program The West Wing.

“‘Cause it’s next,” Alaniz quoted. “‘Cause we came out of the cave, and we looked over the hill and we saw fire; and we crossed the ocean, and we pioneered the west, and we took to the sky. The history of man is hung on a timeline of exploration, and this is what’s next.

“Let’s roll, AFRL.”

Dr. Alex Alaniz, a principal physicist and technical adviser based in the Air Force Research Laboratory, or AFRL’s, Directed Energy Directorate, delivers a speech titled “Helen Keller, ChatGPT and Einstein” at the 2023 AFRL Inspire event at the Air Force Institute of Technology’s Kenney Hall, Oct. 26, 2023. (U.S. Air Force photo / Cherie Cullen)

Dr. Nate Bridges: “Moving Beyond Averages”

Bridges, a research biomedical engineer and program lead in AFRL’s Human Effectiveness Directorate, is motivated by the desire to help individuals reach their full potential by tailoring technologies to fit their unique needs. Bridges, who leads the iNeuraLS program, hopes to revolutionize military training by using technology that personalizes learning to the individual.

“There’s no such thing as average when it comes to people,” Bridges said. “A lot of things in our society are designed for large groups of people, but here’s the thing: we’re all different. We have different needs, different preferences, and yet we’re forced to choose. Imagine a future where we don’t have to choose.”

Bridges and his team have been working to create technologies and capabilities that instantly mold themselves to humans, Bridges said, by building a stronger symbiosis between technology and the human brain.

“It kills me when I see others fail to reach their potential because the technology they are forced to use limits them,” Bridges said. “It kills me when I see technology fail to reach its potential because of the user. This is largely because we design around averages.”

Humans are all different, their needs change over time, and it isn’t always possible to create a device to fit everyone, Bridges said. While there have been some recent improvements in aircraft adjustability and customization to better suit pilots’ needs, Bridges envisions a future in which technology is better integrated with the brain and empowered to adapt to individuals’ needs given what the brain tells them.

Bridges’ team researches how brain activity data can be used to optimize technology for improved cognitive performance when learning and training. To gather and interpret this data, Bridges said, it is necessary to sense (noninvasively read brain signals); assess (understand the meaning of those signals); and then use that interpreted data to augment each individual human.

This could lead to a future where the individual and technology could perform at their greatest potential, Bridges said, as humans could rapidly acquire skills and knowledge when they are needed and multitask more easily, likening this process to the events portrayed in the film The Matrix.

“We limit ourselves by designing to averages,” Bridges said. “Let’s stop designing for the average and instead design for the individual. Demand customization. This promotes inclusivity for those who don’t fall within the average, and that’s going to lead to stronger teams.”

Dr. Nate Bridges, a research biomedical engineer and program lead in the Air Force Research Laboratory, or AFRL’s, Human Effectiveness Directorate, explains in his speech “Moving Beyond Averages” how he and his research team are working to tailor technologies to fit humans’ unique needs at the 2023 AFRL Inspire event at the Air Force Institute of Technology’s Kenney Hall, Oct. 26, 2023. (U.S. Air Force photo / Cherie Cullen)

Dr. Richard Beblo: “Groundbreaking innovation at the speed of failure”

Beblo, a mechanical engineer in AFRL’s Aerospace Systems Directorate, opened his talk by recounting a time when he and his research team conducted a sled test — a type of nondestructive experiment that reproduces the dynamic conditions of a full-scale crash scenario — that “failed” spectacularly. While others present at the testing site deemed the test a total flop, Beblo said, he and his team were ecstatic about their supposed failure.

“We were excited because we knew the test just gained value,” Beblo said. “We knew we were about to learn things that we hadn’t even anticipated as things we needed to learn.”

The quickest path to success is to fail fast and fail often, Beblo said, and this perspective applies to the development of new technologies.

“We need to test new technologies earlier than we think we are ready, for the potential to learn,” Beblo said. “When we do that, failure is not an event — it’s a perspective. When we learn to anticipate failure and not fear it, to use it as a springboard for learning, we will achieve success faster.”

It is crucial to accept risk when conducting experiments and testing new theories, Beblo said, because waiting until there is 100% certainty that a design will work means that one has already waited too long.

“The longer you delay testing, the longer you delay critical opportunities to learn,” Beblo said. “Late failures have long-lasting impacts, but early failures can be corrected; so test as early and often as you can and embrace risk because of the potential to learn.”

Delayed testing results in delayed learning, Beblo said, and while the level of risk and probability of failure stay the same, the cost of waiting increases with time. To learn, one must have the right perspective about their goals, have a plan for success that involves accepting calculated risk, and be prepared for the unexpected, he added.

“The only failed test is a test you didn’t learn from,” Beblo said.

Dr. Richard Beblo, a mechanical engineer in the Air Force Research Laboratory, or AFRL’s, Aerospace Systems Directorate, delivers his talk “Groundbreaking Innovation at the Speed of Failure” at the seventh annual AFRL Inspire event at the Air Force Institute of Technology’s Kenney Hall, Oct. 26, 2023. (U.S. Air Force photo / Cherie Cullen)

Dr. Andrew Gillman: “Striking where the innovation’s hot”

Gillman, a research materials engineer based in AFRL’s Materials and Manufacturing Directorate, described his experience working as part of an extended team of collaborators from industry, academia and government to find a solution to lack of agility in the manufacturing supply chain. Recently, the DAF has confronted challenges in maintaining fleet readiness, Gillman said, as there is an immediate need to obtain small lots of customizable aircraft replacement parts that many manufacturers do not make anymore.

“Why are we struggling to keep our fleets in the air?” Gillman asked. “The problem is similar to maintaining a classic car. Hobbyists do everything to keep these cars in tip-top shape for the car show, pouring time and money into them. But what if that one critical piece breaks? You can’t just go down the road to [your local auto parts shop] and get it; you’ve got to get creative about how you find that part.”

On average, Gillman said, at any given time approximately 30% of the DAF’s fleet of aircraft is in a state of repair and cannot be deployed while aircraft technicians work to acquire the specific auxiliary components and tools needed to successfully complete repairs.

Specialty replacement parts for aircraft are costly and have significant lead times, Gillman said, because many manufacturers no longer see a return on investment for forging them in small lots.

“Maintenance depots need solutions quickly,” Gillman said, “In order to dramatically change this landscape, disruptive manufacturing technologies are needed.”

Gillman partnered with a multidisciplinary development team comprised of AFRL, depot, industry and academia representatives to develop a robotic blacksmithing system that uses incremental forming to craft small lots of customized manufactured parts. The robotic system models the consistency, reliability and agility of a human blacksmith, Gillman said, and can make significant forming decisions on its own without the need for a human operator.

In the future, Gillman added, he envisions robotic blacksmithing as a way to customize medical-grade components for human patients, potentially reducing surgery times and leading to better patient outcomes.

For all of this to work, Gillman said, he embraced a “collaborative beehive of experts” who worked together to find a solution.

“People and robots working together can better develop technology,” Gillman concluded. “Combining the collective knowledge of humans is the best way forward.”

Dr. Andrew Gillman, a research materials engineer based in the Air Force Research Laboratory, or AFRL’s, Materials and Manufacturing Directorate, delivers a speech titled “Striking Where the Innovation’s Hot” at the seventh annual AFRL Inspire event at the Air Force Institute of Technology’s Kenney Hall, Oct. 26, 2023. (U.S. Air Force photo / Cherie Cullen)

Anissa Lumpkin: “The power of influence”

Lumpkin, an operations research analyst and acting mission area lead for AFRL’s Customer Engagement Directorate, shared her experience using the power of influence to impact positive change and close the diversity gap.

While managing AFRL’s Small Business Innovation Research, or SBIR, and Small Business Technology Transfer or STTR, programs, Lumpkin noticed there were no Historically Black Colleges or Universities, or HBCUs, partnered with those programs and resolved to find out why.

“It’s so important to take a hard look at your tables and figure out who is missing,” Lumpkin said. “Then use the power of influence to fill those chairs.”

When she made her initial calls for data to determine how many of the small businesses in her SBIR and STTR programs partnered with HBCUs, Lumpkin said, “the results were alarming. There was zero participation.”

Now that she had the data to show that many chairs at the table were empty, Lumpkin established a plan to fill them, and went on to establish the Department of the Air Force’s HBCU outreach initiative.

As part of this process, Lumpkin said, she asked the Air Force to engage in being part of the solution, got her leadership invested, and ensured that every small business she connected with a HBCU was “aligned” as an excellent match to keep technological capabilities moving forward.

“Inclusion is the celebration of diversity in action,” Lumpkin said. “Moving forward, I ask you: Who is missing? Who is not represented? Think about the teams that you run, organizations that you lead, teams you are a part of, and ask yourself: who is missing from this table?”

The next step, Lumpkin said, is to reach out to them.

“Let them know you value their input, and you want them to be there,” Lumpkin said.

Anissa Lumpkin, an operations research analyst and acting mission area lead for the Air Force Research Laboratory, or AFRL’s, Customer Engagement Directorate, delivers her speech titled “The Power of Influence” at the seventh annual AFRL Inspire event at the Air Force Institute of Technology’s Kenney Hall, Oct. 26, 2023. (U.S. Air Force photo / Cherie Cullen)

James “Sass” Bieryla and Kevin Price: “Amplifying warfighter culture”

Bieryla, director of AFRL’s Strategic Partnering Directorate, and Kevin Price, a computer analyst in AFRL’s Aerospace Systems Directorate, are former active-duty pilots who both lost friends in aircraft accidents, the pair acknowledged as they took the stage together to deliver the final talk of the afternoon.

One way to bring military pilots home safely is to amplify warfighter culture. This means to actively consider the perspective and experiences of Airmen and Guardians when making the decisions or developing the technologies that will directly affect them, Price said.

Price acknowledged that in the early 2000s, he had the opportunity to amplify warfighter culture by chance: he influenced the adoption of a new, more effective coordinate system into the F-16 fighter aircraft and led the design that was transitioned and fielded into over 1,000 USAF and partner F-16s in 2001, Price said. For those troops sent on missions to Afghanistan, the new coordinate system was a major enabler in protecting them. By keeping warfighter culture top of mind, more troops came home safely.

Bieryla recounted his own experience piloting an aircraft on a dark, starless night at Mach-1 when all his navigation displays suddenly went black without warning. In complete darkness, Bieryla was forced to accomplish a complex nine-step procedure to bring his systems back online within a 14-second time frame.

“That’s a lot to remember,” Bieryla said. “What if I did it out of sequence? What if I hit a wrong button? You know, it’s tough enough to do all that here on the ground, but what about at 40,000 feet in the air going 10 miles per minute?”

In those moments, Bieryla said, he wanted the engineers who had designed the nine-step reboot procedure to see things from the perspective of the person flying the plane.

“I would have appreciated a warfighter’s perspective when this technology or procedure was being developed,” Bieryla said. “Because when our warfighters are operating in combat, they don’t have time for a nine-step process that takes 14 seconds.”

Warfighter culture means connecting every Airman and every Guardian to the mission and bringing the end user to the very front of the design process, Bieryla said.

“When we amplify warfighter culture, we multiply mission effectiveness and we save lives,” Bieryla added.

But, Price asked: “How can individuals gain that perspective as a standard operating procedure versus by chance?”

Designers of technology can amplify this perspective by telling and listening to warfighters’ stories and can make them real by going out to meet the people who use the technology, Bieryla said.

James “Sass” Bieryla, director of the Air Force Research Laboratory, or AFRL’s, Strategic Partnering Directorate, left, and Kevin Price, a computer analyst in AFRL’s Aerospace Systems Directorate, right, share their perspectives as former active-duty pilots in their speech “Amplifying Warfighter Culture” at the seventh annual AFRL Inspire event at the Air Force Institute of Technology’s Kenney Hall, Oct. 26, 2023. (U.S. Air Force photo /Cherie Cullen)

Finally, Bieryla added, connect the dots: “Make an operationally informed connection between your technology and the warfighter.”

To close the program, Cain took the stage once more to deliver final remarks.

“I want to give a very special thanks to our speakers today,” Cain said. “I give them those thanks because they had the courage to take on tough problems and the courage to get on this stage. Your guts are inspiring.”

The day’s program provided a glimpse into the people of AFRL, Cain said, and “the fire in all of them.”

Air Force Research Laboratory, or AFRL, Commander Brig. Gen Scott Cain delivers closing remarks to the audience at AFRL’s Inspire event at the Air Force Institute of Technology’s Kenney Hall, Oct. 26, 2023. (U.S. Air Force photo / Cherie Cullen)

About AFRL

The Air Force Research Laboratory, or AFRL, is the primary scientific research and development center for the Department of the Air Force. AFRL plays an integral role in leading the discovery, development and integration of affordable warfighting technologies for our air, space and cyberspace force. With a workforce of more than 12,500 across nine technology areas and 40 other operations across the globe, AFRL provides a diverse portfolio of science and technology ranging from fundamental to advanced research and technology development. For more information, visit www.afresearchlab.com.

Air Force Research Laboratory, or AFRL, Commander Brig. Gen. Scott Cain, far right, and AFRL Public Affairs Specialist and event host Kenneth McNulty, far left, stand onstage with the 2023 AFRL Inspire speaker lineup at the Air Force Institute of Technology’s Kenney Hall Oct. 26, 2023. This year’s program featured 10 distinguished speakers from across the AFRL enterprise who delivered a series of nine live TEDx-style talks designed to inspire listeners and highlight the passion, innovation and pioneering spirit of AFRL’s science and technology workforce. The 2023 roster of AFRL Inspire speakers were unified in driving home the message “One AFRL Team, One Fight.” The program was the first AFRL Inspire event to occur under AFRL Commander Brig. Gen. Scott Cain’s leadership, as well as the first to take place in front of a live and in-person audience since the coronavirus pandemic. (U.S. Air Force photo / Cherie Cullen)