AFRL tests in-house, rapidly developed small engine

WRIGHT-PATTERSON AIR FORCE BASE, Ohio – The Air Force Research Laboratory demonstrated a new and ultra-responsive approach to turbine engine development with the initial testing of the Responsive Open Source Engine (ROSE) on Nov. 6, 2019, at Wright-Patterson Air Force Base.

The Aerospace Systems Directorate’s ROSE is the first turbine engine designed, assembled, and tested exclusively in-house. The entire effort, from concept initiation to testing, was executed within 13 months. This program responds to Air Force’s desire for rapid demonstration of new technologies and faster, less expensive prototypes.

“We decided the best way to make a low-cost, expendable engine was to separate the development costs from procurement costs,” said Frank Lieghley, Aerospace Systems Directorate Turbine Engine Division senior aerospace engineer and project manager. He explained that because the design and development were conducted in-house, the Air Force owns the intellectual property behind it. Therefore, once the engine is tested and qualified, the Air Force can forego the typical and often slow development process, instead opening the production opportunity to lower-cost manufacturers better able to economically produce the smaller production runs needed for new Air Force platforms.

The applications for this class of engine are many and varied, but the development and advancement of platforms that could make use of it has typically been stymied because the engines have been too expensive. Through this effort, AFRL hopes to lower the engine cost to roughly one fourth of the cheapest current alternative, an almost unheard-of price for such technology, thus enabling a new class of air vehicles that can capitalize on the less expensive engine.

“There’s no end to what might be done, but it’s all enabled by inexpensive production,” said Dr. Greg Bloch, Aerospace Systems Directorate Turbine Engine Division chief engineer. “It’s the ability to turn the economics of warfare around.”

Bloch added that the design and development of this engine was a unique learning opportunity for younger engineers within the directorate. By participating in the entire process, from cradle to grave, junior workforce engineers gained first-hand experience with every aspect of engine development.

“We have a lengthy history of providing technical oversight at a high level to various engine companies as they develop these engines for the U.S. Air Force,” said Bloch. “By teaching our people to do this themselves, we’re instilling in them a level of gravitas that will serve the Air Force well when we then apply that oversight to the traditional engine manufacturers.”

The team says ROSE is more than just a first-of-its-kind engine development project. It represents a shift in thinking about how to do business.

“We’re not trying to compete with our commercial partners, we are leveraging an underutilized sector to meet Air Force needs,” said Lt. Col. Ionio Andrus, Aerospace Systems Directorate Turbine Engine Division deputy division chief.

Andrus added that by working closely with other AFRL organizations, including the Materials and Manufacturing Directorate and the Air Force Institute of Technology, the team leveraged internal expertise that helped advance the project. Additionally, by starting from scratch and performing all the work themselves, the AFRL team developed new tools and models that will be available for use in future iterations and new engine design projects.

“This is the right project for the issues that AFRL, the Turbine Engine Division, and the Air Force are facing,” said Andrus. “There’s a lot of goodness here.”

Following this test event, the team will use the measured data to validate their newly-developed design tools and will work toward developing a second iteration of the engine that will be smaller and lighter. With the tools and know-how already in place, Lieghley expects the second design to be completed even more quickly than the first.

Bloch calls ROSE another milestone in the Turbine Engine Division’s rich legacy in equipping Air Force platforms. However, this one holds a special place in the hearts and minds of the engineers behind it.

“There’s not an Air Force engine fielded today whose technology can’t be traced back to Turbine Engine Division in-house work,” he said. “We’ll eventually hand this off to a manufacturer, but this one is all AFRL on the inside.”

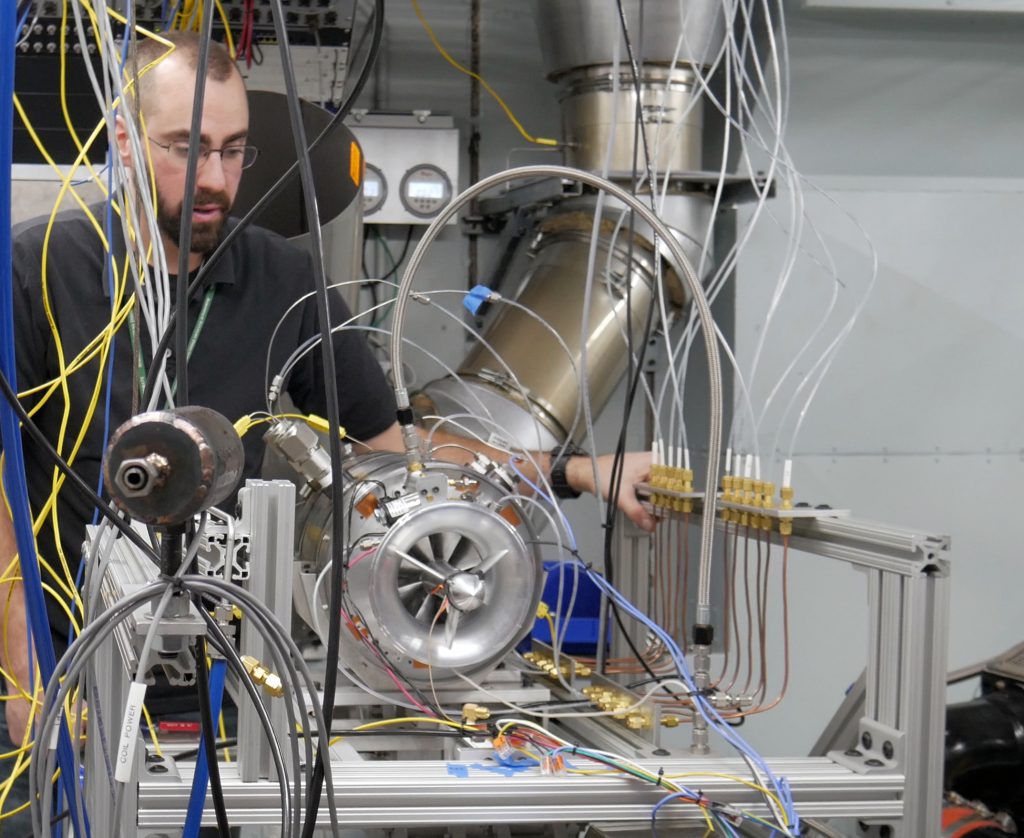

Air Force Research Laboratory engineer Justin Reinhart makes final adjustments on the Responsive Open Source Engine on the test stand. ROSE is a rapid development effort executed within 13 months and is the first turbine engine designed, assembled, and tested exclusively within AFRL. (U.S. Air Force Photo/David Dixon)

Air Force Research Laboratory engineer Justin Reinhart completes final assembly of the Responsive Open Source Engine turbine in preparation for testing. ROSE is a rapid development effort executed within 13 months and is the first turbine engine designed, assembled, and tested exclusively within AFRL. (U.S. Air Force Photo/Tim Bergeron)