AFRL’s Aerospace Systems Directorate granted patent for innovative control surfaces technology

WRIGHT-PATTERSON AIR FORCE BASE, Ohio – Researchers from the Air Force Research Laboratory’s Aerospace Systems Directorate recently secured a patent for their control surface technology after successfully developing and demonstrating additively manufactured, multi-material conformal control surfaces for aircraft wings.

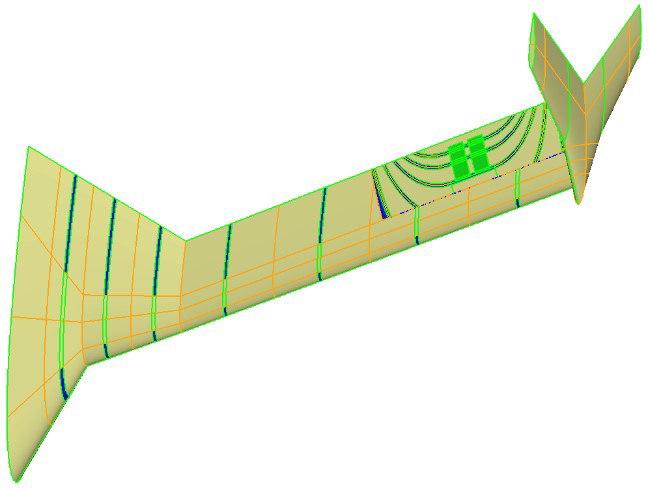

“This technology is a method for designing a smooth, morphing aileron for an aircraft wing, where the aileron contains no gaps for aerodynamic losses and is 3D-printed using soft and stiff materials at the same time,” said Alex Pankonien, an Aerospace Systems Directorate research engineer.

“The invention outlined in this patent offers multiple advantages over today’s conventional flap and slat designs in terms of aerodynamic efficiency, structural integrity and operational capability,” said Ryan Durscher, an Aerospace Systems Directorate research engineer. He added that the invention furthers “a core part of AFRL’s mission” by developing and refining technologies that ensure future air dominance.

The team said that this method for fabricating control surfaces will help advance the understanding of conformal control surface development through direct application to quick-turn aeroservoelastic wind tunnel models for the validation of next generation aircraft designs.

“Many aircraft designers have their own proprietary techniques for developing next-generation morphing ailerons for aircraft that can reduce aerodynamic and acoustic losses,” said Pankonien. “This patented fabrication technique gives AFRL its own intellectual property that can be used to explore designs similar to industry with rapid ground-testing techniques.”

Researchers across the U.S. Air Force are using similar solutions to create cost-effective, optimized aerospace technologies as part of a digital transformation.

“Meeting the Digital Century Series goals for generating and flying more aircraft designs in a timely manner starts with effective ground testing techniques and design methodologies that more efficiently use the resources that we have,” said Pankonien. “Digital engineering takes many forms. Being smarter, even at the level of an aircraft’s control surfaces, is as essential as rethinking the frameworks that we use to explore them,” he said.

AFRL showcases an illustration of the location of morphing control surface on a representative half-span wind tunnel model, Sept. 2, 2021, at Wright-Patterson Air Force Base. This illustration highlights the innovations the Aerospace Systems Directorate team achieved in advancing aileron technologies. (Courtesy Image)