WRIGHT-PATTERSON AIR FORCE BASE, Ohio (AFRL) — AFWERX, the DAF’s innovation arm and a functional directorate within the Air Force Research Laboratory, or AFRL, has awarded a Small Business Innovation Research, or SBIR, Direct to Phase II contract of approximately $1M to Miamisburg, Ohio-based company Cornerstone Research Group, Inc., or CRG, to fund the development of more sustainable and affordable maintainer fabricated enclosure kits, or MFEKs, to improve fleet readiness for the U.S. Air Force.

A MFEK is a pre-fabricated walk-in enclosure, akin to a pop-up tent, that rapidly enables maintainers to perform sustainment on the Air Force’s current fleet of combat aircraft.

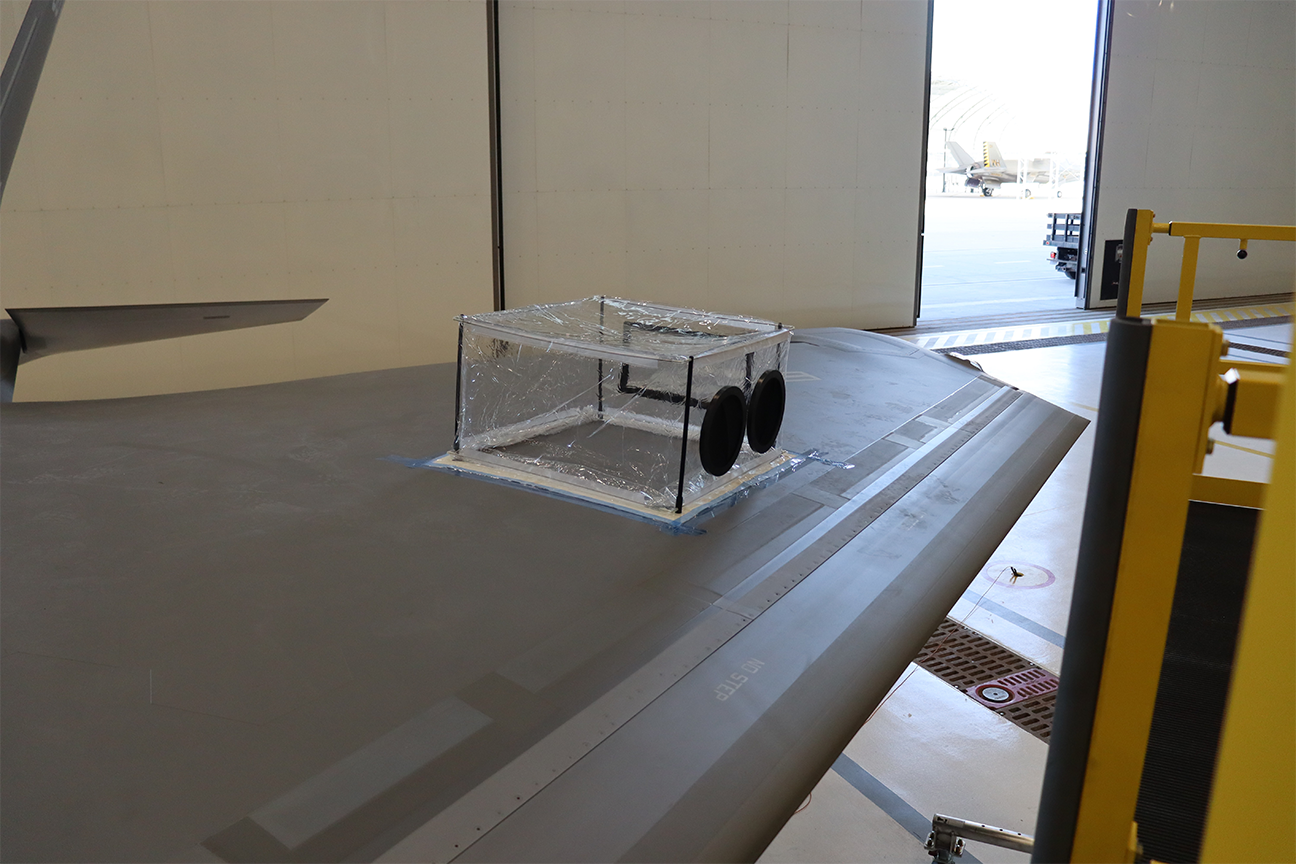

A DIRT Bag 6090 maintainer fabricated enclosure kit, or MFEK, is set up for an on-aircraft demonstration of a structural repair in a hangar at a Marine Corps Air Station facility in July 2022. A MFEK is a pre-fabricated walk-in enclosure that rapidly enables maintainers to perform sustainment on the Air Force’s current fleet of combat aircraft in a controlled, dust- and debris-free environment that works the same way for every maintainer, every time. The enclosure is comprised of durable, transparent panels and a lightweight, reconfigurable frame made of telescoping poles, and is scalable and reconfigurable from 54” up to 90”. AFWERX, the DAF’s innovation arm and a functional directorate within the Air Force Research Laboratory, or AFRL, funded the design, development and successful flightline testing of Cornerstone Research Group’s DIRT Bag DB-6090, which will be sold alongside the smaller DIRT Bag DB-2424 model previously developed under an AFRL Small Business Innovation Research program. (U.S. Air Force photo)

The contract, awarded in February 2022 and scheduled to run through June 2024, funded the design, development and successful flightline testing of a MFEK trademarked by CRG as the DIRT Bag DB-6090. The DB-6090 will be sold alongside the smaller DIRT Bag DB-2424 model previously developed under the SBIR program. Multiple prototypes of the product have been successfully field-tested at various military testing sites, including Luke Air Force Base, Arizona, and the San Diego, California-adjacent Marine Corps Air Station Miramar and Naval Air Station North Island, among others.

Now, representatives from AFRL, CRG and the F-35 Joint Program Office, or JPO, have set their sights on transitioning the technology DOD-wide. Planned next steps include completion of a successful pilot production run in early 2024 and the issuing of a national stock number, or NSN, for streamlined procurement. A NSN documents a product’s viability for use and permits any DOD-related organization to order it, said Kara Storage, CRG SBIR program manager and materials engineer in AFRL’s Materials and Manufacturing Directorate.

Cornerstone Research Group’s DIRT Bag DB-2424, a small 24” x 24” x 20” portable maintainer fabricated enclosure kit, or MFEK, that includes two hand ports, one hose port and one filter for routine maintenance, is set up for flightline testing on an aircraft wing at a Marine Corps Air Station facility in Dec. 2023. The DB-2424 enables debris- and dust-free structural repairs on localized areas of an aircraft and provides a controlled work environment that works the same way for every aircraft maintainer, every time. The DB-2424 is a sister product of and can be paired with the DIRT Bag DB-6090, a larger walk-in enclosure kit that is also portable, scalable and reconfigurable from 54” up to 90”. Both prototypes were developed under an Air Force Research Laboratory Small Business Innovation Research program. (U.S. Air Force photo)

“Polymeric materials require specific environmental conditions for application, and maintainers need the ability to perform technical order procedures using reliable, user-friendly equipment,” Storage said.

When paired with an Environmental Control Unit, or ECU, the MFEK offers a temperature- and humidity-controlled repair environment, keeps the workspace free of potential contamination from dust, dirt and debris and ensures that coatings cure successfully so aircraft can be returned to service more quickly, Storage said.

While these types of outer moldline material repairs can be performed in an aircraft hangar or depot, Storage added, these locations are not always accessible or climate-controlled, have slow cycle times and often bear large support equipment footprints that can be unmanageable for aircraft maintainers.

The F-35 weapon system, crucial to the current Air Force fleet, can also be a particularly challenging aircraft to maintain, said Josh Adkinssetty, CRG project lead and technology transition specialist.

“If it’s cold outside, OK, now maintainers have to pull it into the hangar [to maintain it], and that might mean needing to play musical aircraft, because at any given time they have all of these other aircraft that they know need worked on,” Adkinssetty said. “So, how do you manage all of that? This piece of gear [the DB-6090] kind of takes that out of the equation. I can go set this thing up on the flight line, throw a heater on it, control my environment, and perform the work that I need to, and it reduces the mean downtime between flights.”

Adkinssetty said the DB-6090 addresses a widespread need for a standardized version of the MFEK that works the same way for every maintainer, every time.

While MFEKs can provide the necessary repair environment when hangars are unavailable, historically, aircraft maintainers have been required to cobble the kits together themselves using materials like PVC pipe and bagging material purchased at big box stores, said Adkinssetty. These jerry-rigged enclosure types are customized to suit the unique requirements of each individual repair procedure and are typically discarded after a single use.

Another troublesome aspect of these single-use MFEKs, Adkinssetty noted, is the cost and waste incurred when troops prepare to deploy to remote or austere locations where controlled repair environments are not readily accessible.

“They have to be prepared for anything,” Adkinssetty said. “So, they go out and buy a lot of [material] in hopes that they’re covering everything that they might need and that creates a large footprint. They’re essentially engineering something new every time and throwing it together. And then, next time, if they need it a foot larger, guess what? They have to remake the whole thing.”

The AFWERX SBIR-funded DB-6090, by contrast, is reusable and can be positioned at varying locations on the aircraft, making it a more affordable, sustainable and reliable option for the Air Force, Adkinssetty said.

The 60” x 90” x 60” walk-in enclosure, comprised of durable, transparent panels and a lightweight, reconfigurable frame made of telescoping poles, is also scalable and reconfigurable from 54” up to 90”, as exhibited in numerous aircraft demonstrations. Multiple kits can be joined together to make larger enclosures as needed, and the frame can be reconfigured to various heights and shapes. Excess cover material helps seal gaps to the floor or airframe, keeping the workspace clean and temperature controlled. A variety of cover materials can be provided, if needed, to be tailored to the tasks (i.e., sight-sensitive work, hot work such as welding, ultraviolet cure, etc.).

The kits are not cumbersome and are easy to carry, Storage said. A single kit fits inside of a 1’ x 1’ x 6’ rolling storage bag, and a team of two can set it up or take it down in less than thirty minutes.

“This is a simple piece of gear. It’s not over-engineered, it’s not something crazy that takes, you know, three hours to set up,” Adkinssetty said. “We can move it around; we can reconfigure it to different shapes. It fits into a ski bag with wheels. One [maintainer] can wheel the thing down the flight line and, grab a buddy to set it up in 10 minutes and go about their day.”

All of these factors help reduce maintenance downtime, ensuring that aircraft are returned to service more quickly.

According to a FY 2021 Annual Report, in July 2021, lack of availability of support equipment to conduct maintenance efficiently was cited as a primary challenge to organizational-level maintenance. As the F-35 is a multi-mission platform, inability to conduct all required missions limits its effectiveness.

However, Storage said, while the F-35 JPO has been a “key customer” as the DB-6090 has been developed and a strong advocate for the procurement of a product NSN, its potential military and commercial applications extend far beyond F-35 sustainment.

“It is a pervasive enterprise solution, providing a controlled environment for routine outer moldline maintenance, for multiple weapon systems and other applications or industries,” Storage said.

The multi-use enclosure, with its ability to offer dust and debris containment and hazardous materials protection, has positive implications for future use in clean room activities, the medical, construction and commercial aviation industries, and other branches of the U.S. military. It pairs well with CRG’s DIRT Bag DB-2424, a smaller 24” x 24” x 20” portable kit enclosure which includes two hand ports, one hose port, and one filter for routine maintenance.

An aircraft maintainer demonstrates a representative aircraft structural repair using Cornerstone Research Group, or CRG’s, DIRT Bag DB-2424, a small 24” x 24” x 20” portable maintainer fabricated enclosure kit, or MFEK, at a CRG facility in 2010. The versatile product can accommodate a wide range of aircraft maintenance procedures such as grinding, sanding, temperature control, humidity control and foreign object debris containment. The DB-2424, which pairs with the much larger DB-6090 MFEK, was previously developed under an AFWERX Small Business Innovation Research contract. (U.S. Air Force photo)

“A lot of our focus has been on F-35, but this goes way beyond that,” Adkinssetty said.

Initial field testing indicates that aircraft maintainers want access to DB-6090 and the DB-2424 sister product now — they don’t want to have to wait, Storage said.

“The most exciting part of all of this, for me, has been to actually see this product in action, to get to see the maintainers use it and to get feedback on how it could be useful, and how it makes their jobs easier,” Storage said.

While the positive feedback has been heartening, Storage said, the DB-6090 isn’t yet currently available for widespread standardized distribution due to NSN procurement and, particularly for the Air Force, the desire to pair a reliable ECU prototype with it. Reliable, user-friendly ECUs are also needed for an MFEK to work properly for F-35 coatings repairs.

“We’re kind of stuck right now on the ECU part — that part hasn’t been funded yet,” Storage said.

Storage is hopeful that it will be soon, as CRG is currently working on sourcing a reliable ECU solution, and a teaming agreement with a preferred supplier is in process as CRG targets a pilot product test run by the end of 2024.

CRG is currently coordinating with AFRL to showcase its product in working group meetings and industry conferences, as well as program offices to identify paths to transition, Storage said, so that eventually the DB-6090 can be made available as a commercial off-the-shelf item as well as available DOD-wide pending NSN attainment.

While AFWERX, an AFRL technology directorate that accelerates agile transition of small business technology, officially awarded the SBIR contract in 2022, the effort was in the works long before, Storage said. JFWORX, or Junior Force Warfighter Operations in RX, a group of junior scientists, engineers and program managers based in the Materials and Manufacturing Directorate, create rapid solutions for near-term warfighter needs and initially identified the need for standardized MFEK equipment. JFWORX provided the initial seed money to develop the project in 2018 under the leadership of Sarah Katie Thomas, a materials engineer based in AFRL’s Materials and Manufacturing Directorate.

Cornerstone presented and won JFWORX’s seed money contract bid for their DB-6090 solution, but due to the coronavirus pandemic, there were delays in obtaining the additional funding required to see the project to fruition. Funding from both organizations ultimately resulted in the 2022 SBIR contract award enabling the project to move forward, Storage said.

“I think that the most intriguing part about this is we’re providing [maintainers] in the field with something that’s simple and that works,” Adkinssetty said. “Those two things sometimes don’t go together.”

With approximately four months left on the AFWERX SBIR contract with CRG, Storage said , while she and her team of collaborators have already accomplished a significant portion of what they originally set out to do, there are still a few key undertakings left for implementation.

“We’ve achieved the goal of providing a solution that allows for efficient and affordable sustainment in a controlled environment that has a reduced logistics footprint and saves time,” Storage said. “We’ve accomplished that. Now, we’re focused on transition and getting the product into the hands of the warfighter.”

About AFRL

The Air Force Research Laboratory is the primary scientific research and development center for the Department of the Air Force. AFRL plays an integral role in leading the discovery, development, and integration of affordable warfighting technologies for our air, space and cyberspace force. With a workforce of more than 12,500 across nine technology areas and 40 other operations across the globe, AFRL provides a diverse portfolio of science and technology ranging from fundamental to advanced research and technology development. For more information, visit www.afresearchlab.com.