WRIGHT-PATTERSON AFB, Ohio – Air Force Research Laboratory scientists recently patented a new tunable radio frequency (RF) filter design. The new design is for a smaller, lighter, less expensive device that requires much less power than current technology. As the Air Force moves to smaller, more “agile” flying vehicles such as hand-launched drones, reduced size, weight and power (SWaP) for all components become more critical.

RF filters are a standard component in any device that transmits or receives RF signals. A cell phone, for example, operates within a certain frequency range, or bandwidth, assigned by the government. RF filters ensure that a cell phone operates within a particular bandwidth, preventing interference with or from other devices. However, for military applications, the ideal RF filter needs to be tunable.

“If you are on the battlefield, your adversary will likely try to contaminate your signal, something that’s not very hard to do,” said project team leader Dr. Michael Page. “We have the ability in place right now to tune the filter to remove undesirable signals while preserving intended functionality.”

Although the RF filter can be tunable by an operator, the best technology is “intelligent,” that is, it automatically searches for the best “noise-free frequency,” and then automatically switches to it. The most common tunable RF filter currently in use is a bandpass filter.

“A bandpass filter is based on an electromagnet,” said Page. “It has a little magnetic sphere about the size of the point of a pen. That little sphere sits inside an electromagnet. When you change the magnetic field of the electromagnet, that changes the way the sphere behaves, which changes the operating frequency of the filter.”

Even though it works well, there are practical problems with the current technology.

“Electromagnets are fairly large,” said Page. “They can’t be miniaturized and they use a lot of power. On a larger platform, that’s not an issue, but the way the Air Force is moving, we expect to have a lot of smaller autonomous platforms, drones, where you can’t use a big bulky filter with an electromagnet and a big power supply.”

Current technology is based on an yttrium iron garnet (YIG) magnetic sphere, which is, according to team member Dr. Piyush Shah, about the size of a hockey puck. “The power unit currently used is about the size of a shoebox,” added Shah. “Our filter is about half the size of a matchbox, everything integrated.”

Instead of a YIG electromagnet, the new design uses a layer of piezoelectric material, a material that becomes electrically charged when subjected to pressure. That layer is coupled with a very thin film of permanently magnetized material. “The result,” said Page, “is a low-power, frequency-agile, small, light-weight, RF-tunable device at a much lower cost. Maybe one percent of the cost of current technology.”

“At its heart,” said Page, “the technology we’re looking at is actually very similar to what’s used in modern cell phones. Cell phones have these types of filter banks, but they’re not tunable. The tunable technology depends on big bulky components. We’re trying to get the tunable capability in a compact device similar to the size of a cell phone.”

“Today’s top-tier smartphones use about 50-70 tiny filters to operate in different frequency bands,” said Shah. “More RF filters occupy too much valuable space on the smartphone circuit board, and therefore we believe our invention could potentially decrease the number of RF filters by replacing them with tunable filters.”

“The technology is not restricted for cell phone devices, but other forms of wireless communication systems as well,” added Shah.

“AFRL began work on this technology about five years ago, but specifically the idea of the patented technology evolved in December 2016,” said Shah. “We have shown the fundamental physics of the device and possible functionality of the proposed invention,” said Shah. “”Our next goal is to improve the application-relevant performance metrics of our device.”

Page hopes to have a workable prototype in three to six months. “We submitted the patent on the concept in 2017,” he said, “and we’ve been working on it ever since. So, we are actually farther ahead on the project now than we were when we filed the patent’s paperwork.”

The team hopes that their progress in developing the technology will be significantly accelerated as a result of their newly formed partnership with Sandia National Laboratory.

“The prototype will be as good as the type of technology it is replacing,” said Page, “but of course it will have its own advantages. It will be much smaller in size and weight and it will need much less power.”

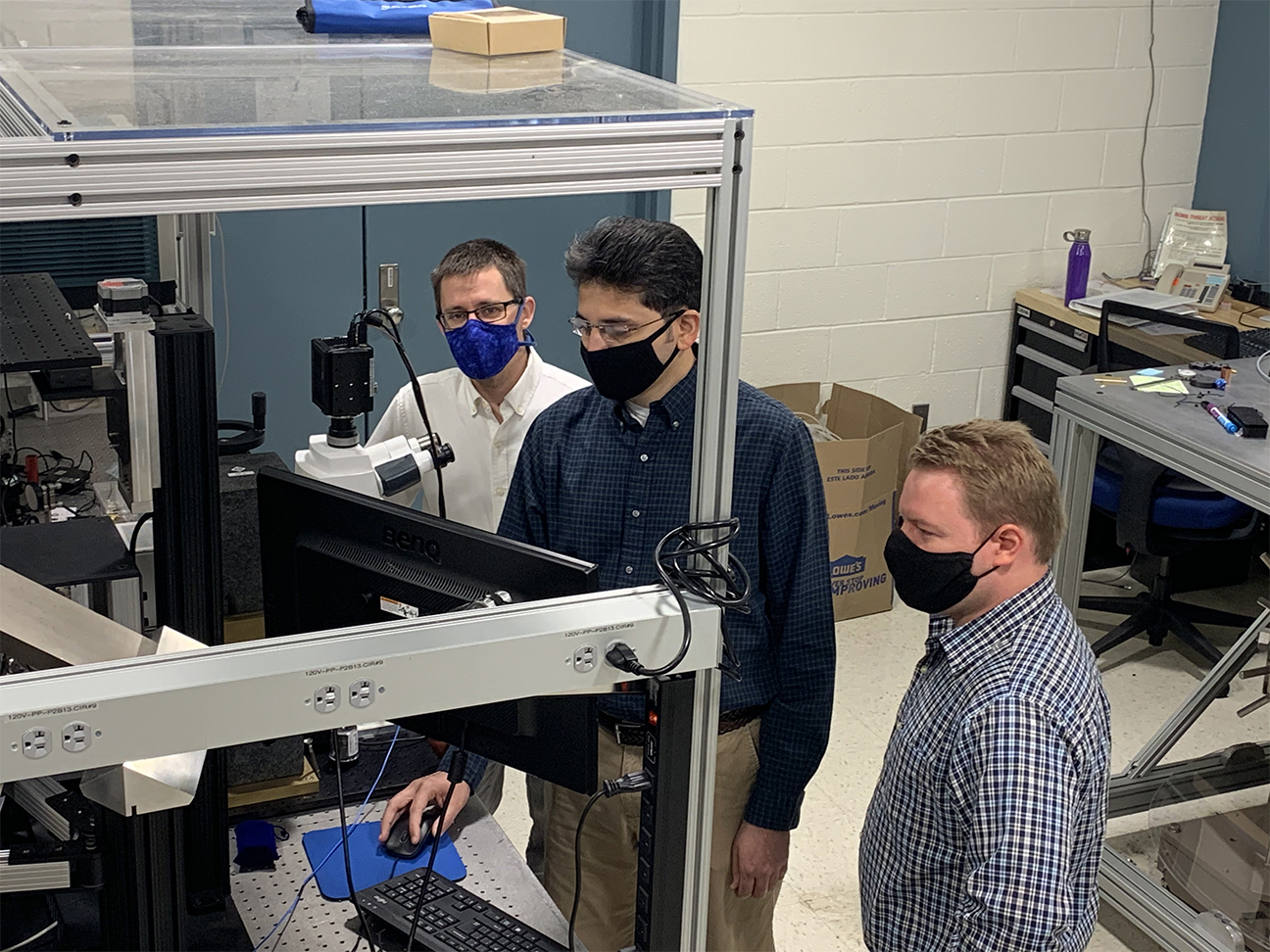

From left to right: Dr. Derek Bas, Dr. Piyush Shah and Dr. Michael Page examine a potential acoustically driven ferromagnetic resonance material under a microscope in the magneto-optics lab. The microscope is designed to observe magnetic properties on a small scale. (U.S. Air Force photo/Michael Wolf)