ADAPTIVE RADOME DIAGNOSTIC SYSTEM (ARDS)

WHAT IS IT?

The ARDS Program is a fully autonomous mobile collaborative robotic system that maps the local electromagnetic response of JSTARS radomes using the Advanced Microwave Mapping Probe (AMMP) RF sensor to indicate mechanical defects on the radome, such as delaminations, excess adhesive resin and waterlogging. The process for ARDS to autonomously scan the JSTARS radome is about four times faster than the current manual process. The addition of ARDS to the Commodities Maintenance (CMXG) organization at RAFB provides a new, quantitative way to validate the quality of radomes and keep a digital record of each radome’s health throughout its lifetime. While ARDS currently supports JSTARS radomes, it is being adapted for F-15 radomes in the near future and can easily be modified to support all aircraft radomes across the Air Force fleet.

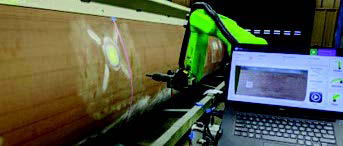

ARDS performing inspection on JSTARS radome at WR-ALC.

KEY BENEFITS

- First implementation and deployment of a fully autonomous mobile robot in a DoD depot

- Easily adaptable to different aircraft radomes

- ARDS demonstrated a 75% reduction in cycle time of JSTARS radome refurbishing

- Deploying a mobile solution avoided facility capital and installation costs of over $500,000 and four weeks of facility downtime

HOW DOES IT WORK?

The effort adapted a Small Business Innovation Research (SBIR) developed spot-probe technology, originally intended for aircraft transparencies, to diagnose aircraft radomes. This spot probe, Advanced Microwave Mapping Probe (AMMP), is a new wideband microwave probe technology designed for use in materials or surface characterization. AMMP was combined with emerging developments in autonomous mobile robots to automate scanning of the entire radome surface. New expert system algorithms were developed to translate the measured microwave spectra into actionable information about the radome health. These critical technologies enabled microwave measurements in high-temperature factory or depot environments, specifically for diagnosing radome health and repair performance.

WHY IS IT IMPORTANT?

Air Force depots must continually repair and refurbish aircraft radomes over their lifetime. Additionally, measuring radome health early and efficiently is a growing need in Air Force sustainment. However, as radomes age, defects are difficult to detect and current diagnostic methods, such as the tap test, provide only qualitative information.

ARDS solved a pressing need for JSTARS and looks extremely promising for other challenging radome inspections. ARDS demonstrated a 75% reduction in the cycle time of JSTARS radome repair. Deploying a mobile solution saved more than $500,000 in facility capital and installation costs. Additionally, the mobile solution saved four weeks of facility downtime during installation compared to a traditional fixed robotic implementation. Finally, ARDS provided novel and valuable defect classification (e.g., delamination, excess resin, crushed honeycomb and water damage). This information helps the maintainer select the proper repair process and track radomes’ overall health integrity through their lifecycle.

The ARDS system developed in this effort can be adapted to other aircraft, ranging from older legacy platforms, such as the F-15 and C-130 variants, to the newest aircraft, such as the F-22, F-35 and B-21. Thus, the cost savings along with the efficiency and accuracy improvements of this diagnostic method may be translated across the Air Force fleet, resulting in significant improvements to depot costs and throughput.

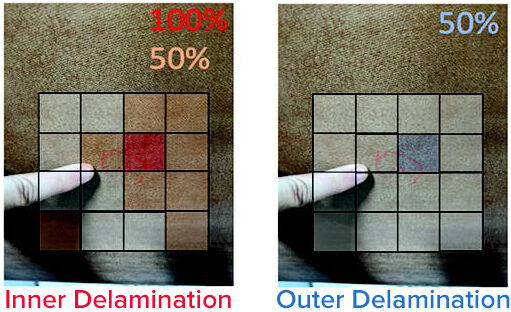

ARDS defect detection results superimposed on top of mark indicating

delamination found via tap-test.

ADDITIONAL FACTS

The transition of this ARDS technology is occurring now with active follow-on efforts applicable to the F-15 radomes. In particular, the new data available from ARDS can potentially supplement or even replace radar range verification measurements of radomes. Ongoing work is now not only adapting ARDS to F-15 nosecones but also developing the data processing capability to calculate overall radome performance from the ARDS-mapped microwave data. Such extensions could provide significant cost and time savings as the existing radar range measurement techniques require expensive facilities. The F-15 SPO is also evaluating the radome data collected by ARDS to aid in the advisement of forward-deployed units. Once a digital twin of the radome is created, the field unit can leverage the handheld probe to collect data from a damaged radome and send that data to the depot for evaluation. Merging the field data with the digital twin can provide a clear picture of the damage and inform the overall health of the radome.

ARDS short reach performing inspection on JSTARS radome at WR-ALC.