MUTANT

MISSILE UTILITY TRANSFORMATION VIA ARTICULATED NOSE TECHNOLOGY

WHAT IS IT?

AFRL aims to significantly increase missile range and lethality against highly maneuverable targets with a better flight control actuation system. The MUTANT program’s approach is a form of active morphing involving high-rate pivoting of the missile forebody, referred to as articulation.

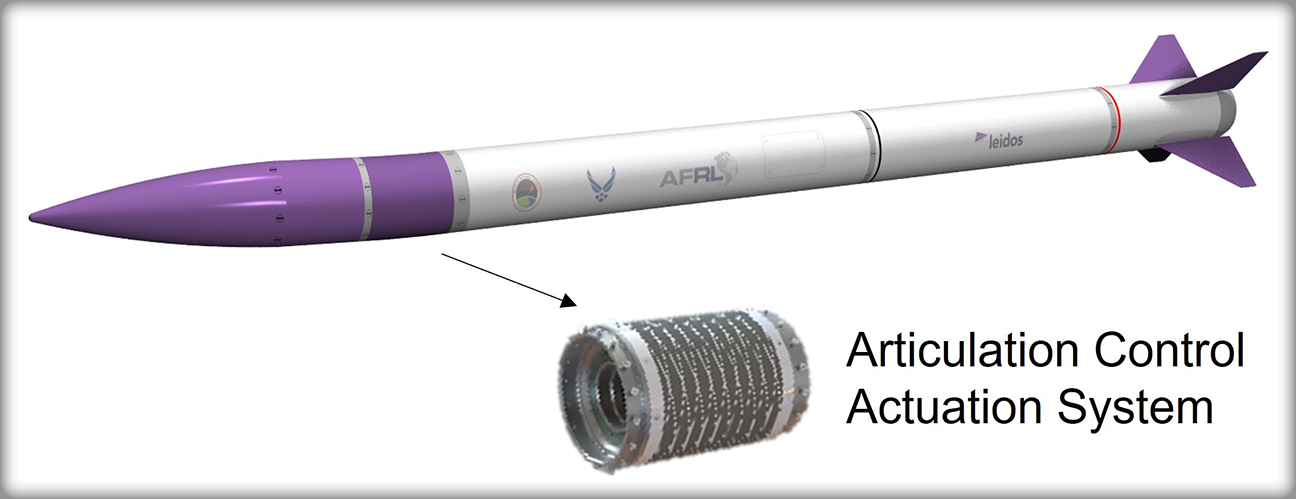

Articulation is accomplished with an articulation control actuation system (ACAS), comprised of a composite high-strain skin structure that envelops an internal electromagnetic actuation system. With a single articulated joint, the missile forebody is used as a flight control surface to augment air-to-air axisymmetric missile effectiveness.

With six years of basic and applied research investment, AFRL understands how to design, fabricate, integrate and employ the ACAS to improve missile performance.

AFRL advances ACAS technology readiness through laboratory and ground test events. From mid-fiscal year 2023 to the end of 2024, AFRL will perform three ground tests culminating in dual articulation and fin control in maneuvering a modified Hellfire missile. The Hellfire is used for research purposes and is not necessarily the intended application of the ACAS.

KEY FACTS

- AFRL leadership: Though ACAS has been researched, AFRL is the first to design, build, integrate and test at full scale

- Broad application: The ACAS is an enabling technology suitable for both air and surface launched missile

- Test focused: AFRL will advance ACAS missile readiness with three ground tests between FY23 and FY24

HOW DOES IT WORK?

Many articulation ideas are outlined in patent literature, but they are not all plausible for supersonic missile environments. One promising approach involves rotating segments with canted interfaces. In concept, the action is similar to the F-35 Joint Strike Fighter vertical takeoff and landing swivel nozzle.

AFRL developed an electronically-controlled actuation system comprised of compact electromagnetic motors, bearings, gears and structures. Careful design allows a circular passthrough for component wiring into the aircraft body. A composite skin structure protects the actuation components from the environment while maintaining a smooth outer mold line (OML).

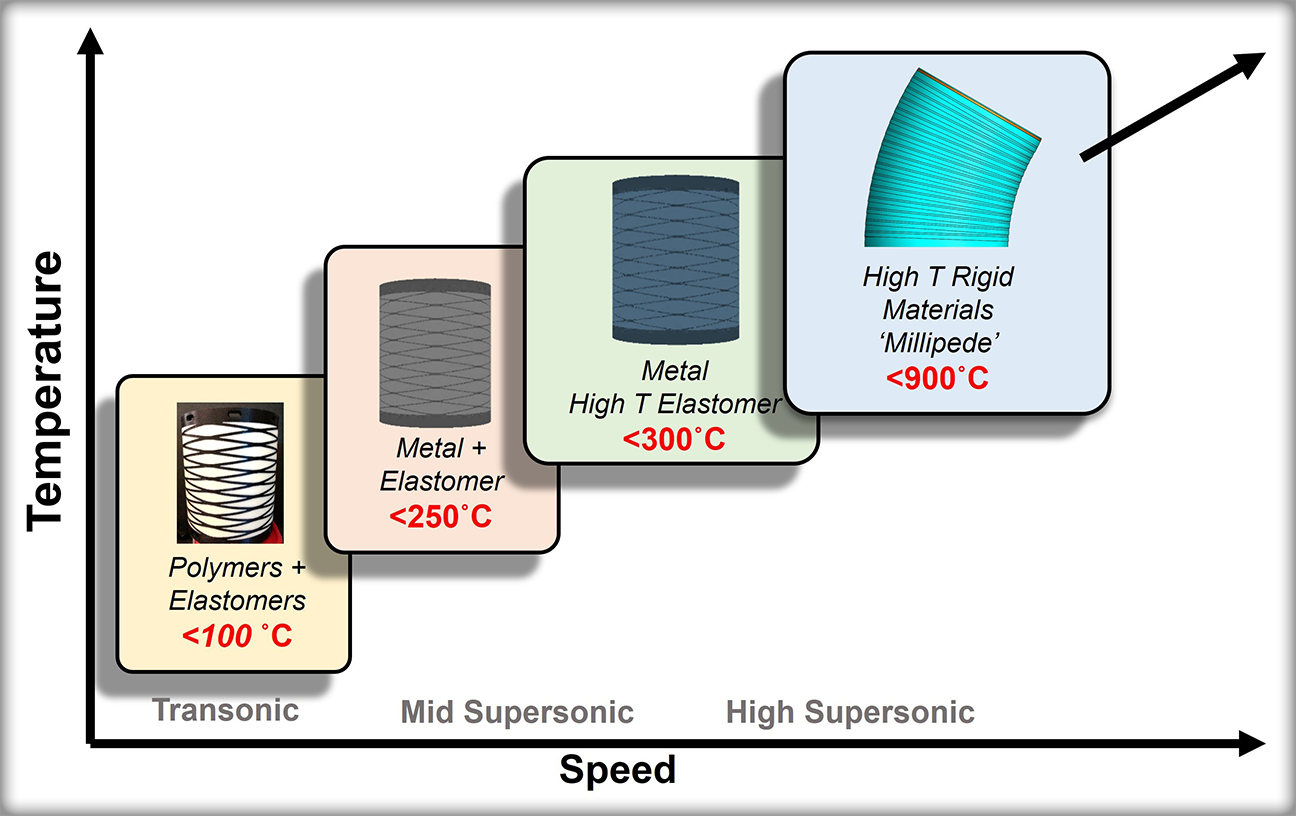

A homogeneous material may be most practical for the skin, but engineering requirements led to the a composite structure involving a metallic internal skeleton that is infilled with an elastomer. The combination of these materials, along with special design of the skeleton topology, allows smooth bending while still carrying a portion of the loads. Three skin concepts have been developed to various technology readiness levels with details given in the figure on the left.

Progression of composite skin structure materials and form as severity of environment increases. Note: The Mid Supersonic skin will be used for the remaining ground tests, with High Supersonic skin concepts delivered in FY24.

WHY IS IT IMPORTANT?

Next generation air dominance (NGAD) requires broad advancement in manned and unmanned aircraft, their family of weapons systems, and the communication between them. Medium and long-range air-launched missiles are a key component of Tactical Air Dominance and Resilient Basing (USAF Operational Imperatives 4 and 5). ACAS technology is directed at fulfilling future NGAD requirements through the intercept of highly maneuverable targets or threats at longer range with limited cost.

US weapons technology advancement primarily involves fixed OML geometries that reflect a design compromise over the various stages of weapon delivery (e.g. launch, boost, cruise, terminal homing, end game). For example, what is aerodynamically good for range is not good for maneuverability. Morphing weapons technology allows continuous OML change to tailor performance to each phase of flight. Historically, size, weight and power of morphing technology has been prohibitive to a missile system level benefit. MUTANT is in the midst of tipping the scale in the morphing weapon’s favor.

ADDITIONAL FACTS

A more effective missile tends to have more range, maneuverability (g-capability), and agility (airframe responsiveness) with limited weight. The missile control actuation systems (CASs) affects all three of these metrics, and hence the ability to effectively to close in on targets.

Each CAS, or CAS combination, such as dual canards and fins, have distinct and strong implications to overall missile performance. CASs good for range (fins only) tend to be bad for maneuvering and agility. CASs good for maneuverability and agility (canards, wings, jets, thrust vectoring) tend to be bad for range due to drag or additional weight.

MUTANT reference model OML with second generation ACAS model shown. The purple highlighted areas represent active control surfaces. Skin skeleton and infill is shown in the light and dark areas, respectively.

The ACAS is special. As a conformal surface, aerodynamic drag is not affected in midcourse. In terminal homing, the large surface area of the missile forebody provides tremendous agility and moderate improvements to maneuverability. As a result, with sufficiently low ACAS SWaP (size, weight and power) and sufficiently high performance, a significant net benefit to missile performance is obtained.

Missile articulation is not a new concept. The open patent and technical literature contains reports on articulation going back to the 1950s. AFRL advances the ACAS knowledge base and technology readiness in considering integration and function at the missile system level.

ABOUT AFRL

The Air Force Research Laboratory (AFRL) is the primary scientific research and development center for the Department of the Air Force. AFRL plays an integral role in leading the discovery, development, and integration of affordable warfighting technologies for our air, space and cyberspace force. With a workforce of more than 11,500 across nine technology areas and 40 other operations across the globe, AFRL provides a diverse portfolio of science and technology ranging from fundamental to advanced research and technology development. For more information, visit: www.afresearchlab.com.