AFRL is developing green power for satellites

KIRTLAND AIR FORCE BASE, N.M. (AFRL) — The Air Force Research Laboratory, or AFRL, Space Vehicles Directorate is developing a new “green energy” fuel cell technology, that will allow thruster equipped spacecraft to convert chemical energy in its bipropellant into electrical power.

This technology, called BEEPS for Bipropellant Enabled Electrical Power Supply, is being developed by a three-year Seedlings for Disruptive Capabilities Program effort that recently completed its 18th month of work.

“The solid oxide fuel cells created by this effort will enable bipropellant thruster-equipped spacecraft to convert chemical energy in its bipropellant, into on-demand electrical power,” said Dr. Thomas Peng, program manager for BEEPS. “Such technology would allow spacecraft operators to tap stowed bipropellant to get a boost of electrical power or act as an auxiliary power supply if needed.”

BEEPS research is discovering ways to electrochemically breakdown a variety of fuels and oxidizers to efficiently generate electricity.

“If the fuel and oxidizer combination consumed is hydrogen and oxygen, the exhaust will be water, and if the pair consumed is a hydrocarbon and oxygen, the exhaust will be water and carbon dioxide,” Peng said. ”AFRL and its collaborators want to improve the power we can generate from carbon free fuels, so we can deliver the power people expect from high performance power plants without the use of fossil fuels.”

Peng further detailed additional benefits of this green technology, using a few examples.

“With the fuel cell technology AFRL has developed, we can also create solid oxide electrolysis cells that can electrolyze water into hydrogen and oxygen,” Peng said. “By pairing fuel cell and electrolysis technology, we can set up a rechargeable energy storage system that can have more than 20 times the specific energy and more than 10 times the energy density of state-of-the-art rechargeable lithium ion batteries.”

Peng continued by stating that by combining fuel cell and electrolysis technology, AFRL can establish a carbon free means to provide continuous reliable power by pairing this technology with renewable sources of energy that may not be reliable.

“For example, wind power is only available when the wind is blowing and solar power is only available when the sun is shining,” Peng said. “With the fuel cell and electrolysis technology we are developing, we can efficiently store a large amount of energy collected when wind or solar power is available. This stored energy can then be used to power systems when wind or solar is unavailable.”

This research also puts AFRL on a path where researchers may be able to develop a means to eliminate the detrimental effects of releasing carbon when burning hydrocarbons.

“When large scale generation of electricity that is reliable (and) cost competitive, and carbon neutral becomes commonplace, our solid oxide fuel cell activities could lead to a way to convert carbon dioxide and water back into combustible hydrocarbons by electrolyzing carbon dioxide concurrently with water,” Peng said. “The ability to generate hydrocarbons by capturing and electrolyzing carbon dioxide has been demonstrated in laboratory. Unfortunately, major deficiencies remain with the catalysts used for hydrocarbon synthesis and challenges remain with scale up of the overall process. These are problems our BEEPS work can help resolve.”

In this effort, the Space Vehicles Directorate is working with two other AFRL technical directorates. First, the Aerospace Systems Directorate, which is in charge of designing and manufacturing Solid Oxide Fuel Cell, or SOFC, components and assessing how compatible SOFC components are with common bipropellants. Second, the Materials and Manufacturing Directorate, which is responsible for developing use-cases for BEEPS technology and supporting the Aerospace System’s SOFC component design and manufacturing work.

In addition, major collaborator, OxEon Energy is taking SOFC technology being developed by this effort, and using it to create robust SOFC stacks which can provide useful amounts of power in a single package. Several other collaborators include the University of New Mexico, Tennessee Tech University, Sandia National Laboratories, and the University of Dayton Research Institute.

“This green technology will provide spacecraft operational flexibility by developing a fuel cell that can generate electricity by consuming bipropellant,” Peng said. “This can help ensure that the power needed to complete critical spacecraft operations will always be available when bipropellant is available. Moreover, with a great deal more development, this work can enable the warfighter to create fuel and oxidizer to power operations locally, wherever needed.”

About AFRL

The Air Force Research Laboratory (AFRL) is the primary scientific research and development center for the Department of the Air Force. AFRL plays an integral role in leading the discovery, development, and integration of affordable warfighting technologies for our air, space, and cyberspace force. With a workforce of more than 11,500 across nine technology areas and 40 other operations across the globe, AFRL provides a diverse portfolio of science and technology ranging from fundamental to advanced research and technology development. For more information, visit: www.afresearchlab.com.

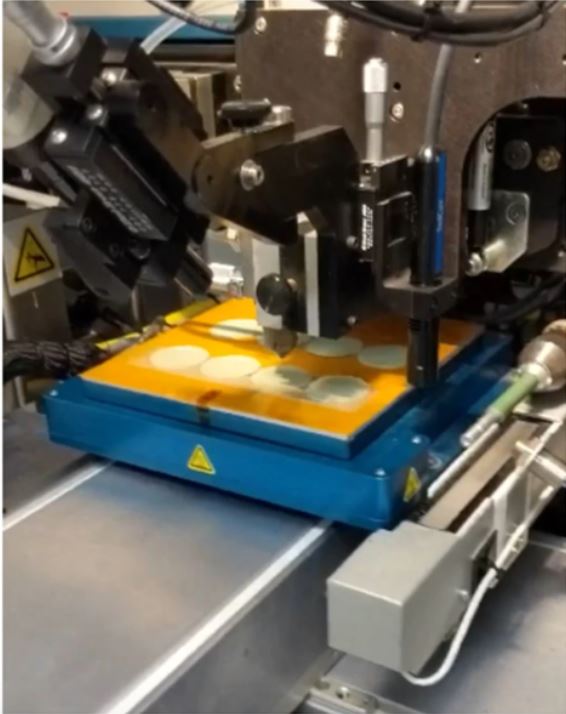

A solid oxide fuel cell stack designed and assembled for the Bipropellant Enabled Electrical Power Supply, or BEEPS, effort by Air Force Research Laboratory collaborator OxEon Energy that is capable of providing stable electric power by consuming a steady flow of bipropellant at Kirtland Air Force Base, New Mexico.

Dr. Andre Spears, an Air Force Research Laboratory Space Vehicles Directorate postdoctoral research fellow from the University of New Mexico, assembles a solid oxide fuel cell for testing, as part of the Bipropellant Enabled Electrical Power Supply, or BEEPS, effort.

Solid oxide fuel cells additively manufactured by the Air Force Research Laboratory, or AFRL, Aerospace Systems Directorate for the Bipropellant Enabled Electrical Power Supply, or BEEPS, effort, using novel aerosol jet printing capabilities at AFRL at Kirtland Air Force Base, New Mexico.