AFRL, National Science Foundation, academia converge in Miami Valley

WRIGHT-PATTERSON AIR FORCE BASE, OHIO (AFRL) — The Air Force Research Laboratory, or AFRL, the National Science Foundation, or NSF, and representatives from some of the nation’s leading academic institutions joined forces at the Wright Brothers Institute in downtown Dayton, Ohio, for the NSF’s Designing Materials to Revolutionize our Future, or DMREF, and AFRL Kickoff Dec. 6-7, 2023.

The two-day event provided a rare opportunity for members of AFRL’s world-class science and technology, or S&T, workforce to share scientific plans with fellow materials researchers from some of the country’s most distinguished universities to accelerate the transition of new materials from design to deployment in support of the nation’s warfighters over the next four years.

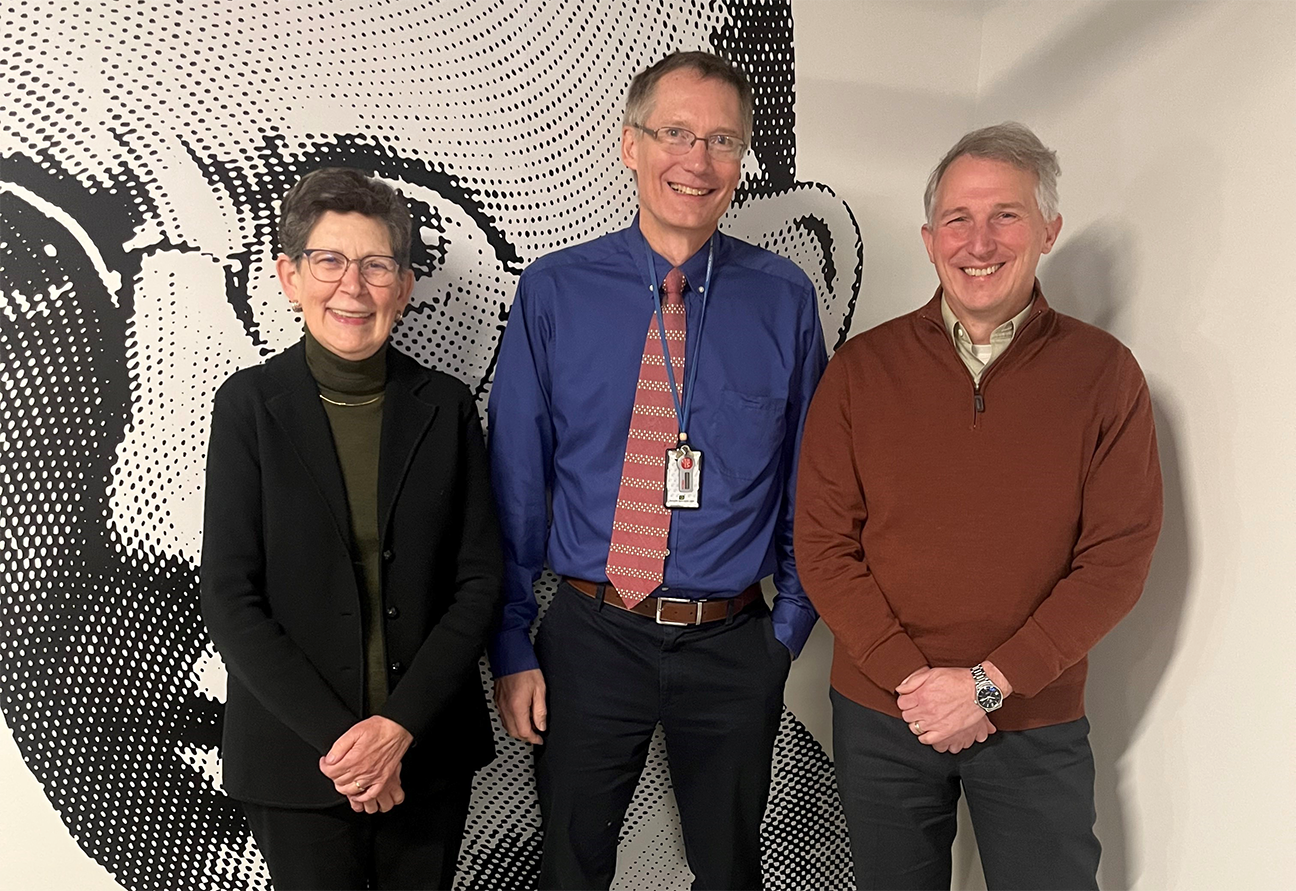

From left: Air Force Research Laboratory, or AFRL, Senior Technologist Dr. Ruth Pachter, who currently holds Emeritus status within AFRL’s Materials and Manufacturing Directorate, stands with Dr. John Schlueter, Designing Materials to Revolutionize Our Future, or DMREF program director, and Dr. Richard Vaia, chief scientist in AFRL’s Materials and Manufacturing Directorate at the National Science Foundation’s DMREF-AFRL kickoff at the Wright Brothers Institute in downtown Dayton, Ohio, Dec. 7, 2023. Pachter and Schlueter’s efforts to rethink interagency partnerships were instrumental in connecting the AFRL workforce with the academic community via the DMREF program, Vaia said. Pachter, with her strong background in materials discovery and development, leveraged her expertise to connect members of AFRL’s workforce across multiple directorates to DMREF project teams with overlapping research interests since 2018. In her Emeritus role, Pachter has sustained these efforts to facilitate the translation of materials discovery to deployment in support of DAF needs. (U.S. Air Force photo)

Twenty-two multidisciplinary materials research teams attended the event, representing multiple principal investigators from a wide range of multi-university projects. The teams’ research projects are funded wholly or in part by a series of grants awarded in 2021 and 2023 through the NSF’s DMREF program to help support the discovery, development and deployment of new materials more quickly and efficiently at a fraction of the typical cost, many in support of the warfighter.

Of the 37 new four-year projects funded in the 2023 DMREF awards cycle, seven are directly tied to AFRL directorates. Roughly a third of the NSF’s DMREF current portfolio, comprised of materials research grants awarded in 2021 and 2023, involve collaborative projects with AFRL’s Materials and Manufacturing, Munitions and Sensors directorates.

In his opening remarks to conference attendees, AFRL Executive Director Timothy Sakulich noted that the city of Dayton — best known for its rich history of innovation and invention — was an apt setting for the two-day gathering of some of the nation’s best and brightest problem-solvers.

“The brain trust that you represent here is pretty phenomenal,” Sakulich said, addressing a crowd of S&Ts from AFRL, academia and industry, many of whom had traveled across the country to represent their materials research teams in person. “Sometimes I think we take for granted the faces behind all the stuff we read about, but ultimately, we’re a people business that does really cool science and solves important problems. Bringing these people together into one room … it’s phenomenal to create critical mass around this incredible brain trust that’s here today.”

Sakulich credited the positive leadership from individuals hailing across multiple sectors with leading the charge to accelerate science and technology and tackling important challenges such as building up the national economy and supporting the nation’s defense.

“We’re in the defense business here at AFRL,” Sakulich said. “Our job every day is to make sure that the young men and women whom we as a nation ask to go and defend our way of life and our values and provide for our national security have the best the nation can offer — the absolute best. We don’t want them to ever be in a situation where they’re at a technological disadvantage. That motivates us every day.”

The NSF established the DMREF program in 2012 as a response to the federal government’s Materials Genome Initiative, or MGI, of 2011. Its goals were to unify the materials innovation infrastructure, harness the power of materials data, and educate, train and connect the materials research and development workforce, said Dr. Richard Vaia, chief scientist in AFRL’s Materials and Manufacturing Directorate.

“Right now, we are in a peer competition … and, fundamentally, that is why I think this partnership across the agencies with the NSF, with the academic community — this multi-agency collaboration — is so critical,” Vaia said. “We have to take the ideas, the concepts, the innovation that is represented here in this room and accelerate it. We have to do good science. We have to engage with the global community. But we also want to pick and choose those problems that are most relevant to the defense of our nation, and it’s this merging of agency missions that I’m so excited about with this partnership. It comes down to, at the end of the day, people collaborating.”

According to a press release, in September 2023, the NSF made a $72.5 million investment in the DMREF program to drive the design, discovery and development of advanced materials needed to address major societal challenges, including growing threats to the nation’s defense, resulting from peer adversary competition.

“Our scientists and engineers are externally recognized as world experts. Because of that, we are actively sought out as partners for our nations’ premier S&T programs — in this case, DMREF. The Pentagon doesn’t have to go to premier universities, for example, to get a complex question answered. They can come to AFRL — as do the folks at these leading institutions.”~Chief Scientist Dr. Richard Vaia, AFRL’s Materials and Manufacturing Directorate

Dr. Tod Grusenmeyer, a research chemist in AFRL’s Materials and Manufacturing Directorate who coordinated crucial event logistics ahead of the kickoff meeting in Dayton, currently serves on an AFRL team that is contributing to warfighting efforts via the NSF DMREF program “Data-Driven Prediction of Hybrid Organic-Inorganic Structures.” The research project, which features academic contributors from the University of Colorado-Boulder, Duke University and New Mexico Highlands University, is working to develop and leverage a new automation capability to accelerate new material discovery.

His team’s collaborative effort, Grusenmeyer said, will produce novel materials applicable to a number of next-generation warfighting capabilities including scintillators (materials that fluoresce when struck by a charged particle or high-energy photon), self-powered photodetectors (a class of devices which requires no external power supply for their operation), solid-state lasers (lasers that use crystals or glass as their lasing medium) and solar cells.

“As a 2023 new-start project, the team is just getting started on this collaboration,” Grusenmeyer said. “We are riding this moment from the in-person meeting and are finalizing the details for of the first set of experiments, planned for early January.”

Dr. Tod Grusenmeyer, a research chemist in the Air Force Research Laboratory, or AFRL’s, Materials and Manufacturing Directorate, shares his research team’s plans to accelerate the transition of new materials from design to deployment in support of the nation’s warfighters over the next four years at the National Science Foundation’s Designing Materials to Revolutionize Our Future, or DMREF, and AFRL 2023 kickoff meeting at the Wright Brothers Institute in downtown Dayton, Ohio, Dec. 7, 2023. Grusenmeyer, who coordinated crucial event logistics ahead of the kickoff meeting in Dayton, currently serves on an AFRL team that is contributing to warfighting efforts via the NSF DMREF program “Data-Driven Prediction of Hybrid Organic-Inorganic Structures.” The research project team, which features academic contributors from the University of Colorado-Boulder, Duke University and New Mexico Highlands University, is working to develop and leverage a new automation capability to accelerate new material discovery. (U.S. Air Force photo)

Dr. Pat Dennis, an AFRL senior research biologist also based in the Materials and Manufacturing Directorate, currently advises and offers critical research feedback to another DMREF team of scholars from Rutgers University and Princeton University that is developing new materials to stabilize protein molecules. The team is leveraging this collaborative effort to enhance and extend the catalytic properties and functional lifetimes of these protein molecules, as well as facilitate their stable incorporations into materials needed in the field such as vaccines and other medications, Dennis said.

“AFRL has a long-standing interest in this,” Dennis said. “For the DOD, increased protein stability can lead to decreased logistic burdens, agile biomanufacturing of materiel at the point-of-need, and the bio-enabling of materials for advanced applications.”

Dr. Adam Gormley, assistant professor of Biomedical Engineering at Rutgers University and nano biomaterials expert, is currently leading that team of researchers in collaboration with Dennis and AFRL. Using artificial intelligence and robotics, Gormley’s team is developing new methods to rapidly discover materials that can greatly enhance the robustness of proteins against temperature-induced degradation. In the long-term, Gormley said, these methods will help prepare sensitive biopharmaceutical drugs for rapid deployment in the battlefield.

“Millions of Americans, including many of our Airmen and Guardians in the Air Force, depend on biopharmaceuticals to maintain their health,” Gormley said. “Many of these biological drugs are highly fragile and therefore require careful refrigerated storage. We saw the effects of this during the COVID-19 pandemic when very cold temperature storage of the mRNA vaccines greatly limited where these drugs can be administered.”

His team is working to address this limitation, Gormley added.

While in the past AFRL has looked at simple protein-wrapping technologies as an effective way to increase enzyme and antibody stability, these techniques can be limited in terms of the range of proteins that may be effectively stabilized, warranting further research, Dennis said.

“The bespoke protein-wrapping technology being studied by Dr. Gormley and his team will not only expand the range of target proteins that may be stabilized but will also streamline their creation, thus decreasing development time and speeding transition to the field,” Dennis said.

From his perspective, Gormley said, his team’s partnership with AFRL has been incredibly productive for the interdisciplinary team, helping to ground the direction of the project to focus on real-world problems that members of the U.S. military currently experience.

“Otherwise, it [would be] too easy for such a diverse team to lose track of our overarching goal to stabilize proteins with practical challenges of stability,” Gormley said. “We are very excited that the NSF, through the DMREF program, has partnered with organizations such as AFRL to provide critical feedback on projects.”

“From my perspective, the future of materials discovery and development, at this time, looks boundless. AFRL is not only providing a path to deployment; it’s also posing really challenging problems, which leads to fundamental research in areas that might not be envisioned otherwise.”~AFRL Senior Technologist Dr. Ruth Pachter, Emeritus, Materials and Manufacturing Directorate

Currently, DMREF’s mission to accelerate the translation of materials from design to deployment is guided by the MGI 2021 Strategic Plan, and DMREF solicits materials research project proposals from multidisciplinary teams across the country that align with its goals, said Dr. John Schlueter, DMREF program director. A panel of qualified reviewers carefully considers the proposals before selecting and awarding NSF funding to those teams that are best positioned to accomplish the MGI mission.

“The MGI has a mission to help businesses discover, develop and get materials to market faster and cheaper than is possible through traditional methods,” Schlueter said. “The idea was to bring together these computational tools, experimental tools and digital data to develop what’s called material innovation infrastructure. And this was designed to be able to accelerate progress in key areas like clean energy and the general welfare, national security, and so on. At the NSF, certainly, we’re very interested in being able to train this next-generation workforce with an MGI-type of mindset.”

“To avoid the ‘Valley of Death’, technologies often require seamless partnerships, and DMREF teams maintain an effective iterative feedback loop to get materials discovery into development faster.”~Dr. John Schlueter, National Science Foundation DMREF program director

Accelerating the progression of fundamental materials research toward deployment and manufacturing is crucial, as valuable discoveries often don’t make it past the development stages, Schlueter said. Promising new technologies can easily languish in what is known amongst the research community as the “Valley of Death,” a dead space where potentially relevant materials are never fielded for use due to lack of funding.

“To avoid the ‘Valley of Death’, technologies often require seamless partnerships, and DMREF teams maintain an effective iterative feedback loop to get materials discovery into development faster,” Schlueter said.

The MGI has 18 federal partners, Schlueter noted, including AFRL, the NSF, NASA, the U.S. Navy, the U.S. Department of Energy and the U.S. Army, among others. DMREF proposals may include federal partnerships to bolster the scientific or engineering aspects of the critical iterative feedback loop to accelerate materials research consistent with MGI principles.

“It’s good that we know where we came from and where we’re going,” Schlueter said. “This is, I think, really what MGI had envisioned, to have these partnerships, to work together, to accelerate materials research toward these real, fundamental societal challenges that we have.”

Dr. Lisa Rueschhoff, a materials research engineer based in the Air Force Research Laboratory, or AFRL’s, Materials and Manufacturing Directorate, delivers a presentation on sintering-assisted additive manufacturing techniques at the National Science Foundation’s Designing Materials to Revolutionize Our Future, or DMREF, and AFRL 2023 kickoff meeting at the Wright Brothers Institute in downtown Dayton, Ohio, Dec. 7, 2023. Rueschhoff has collaborated on a team of researchers from AFRL, San Diego State University and Clemson University to accelerate the transition of new materials from design to deployment in support of the nation’s warfighters over the next four years. (U.S. Air Force photo)

In his remarks to the group, Dr. Germano Iannacchione, NSF Division of Materials Research director, also underscored the significance of the Air Force’s partnerships, past and present, with the NSF to further materials research.

“The NSF and the Air Force have not only this history of deep connections, of working together; each time [we partner] this relationship grows — it doesn’t plateau,” Iannacchione noted. “What this relationship does is expose new frontiers of collaboration and new, exciting questions emerge. I think what we’re seeing today is the emergence of that complexity. We really do need interdisciplinary groups; we do need, desperately, these partnerships because we are asking questions now that we couldn’t even dream of asking just a few years ago.”

While it can be difficult to guess what challenges lay ahead, Iannacchione said, the NSF and the Air Force have developed a paradigm that allows them to explore the unknown in a unified, holistic way to aid in the nation’s defense.

“The NSF’s mission is not only economic, it’s not only workforce development, it’s not only just to make the nation smarter,” Iannacchione said. “Its original charter pledged to support the national defense. We support it in its most fundamental way: we start with the very edge, the bleeding edge, of discovery.”

AFRL currently has an MOU, or memorandum of understanding, with the NSF, Vaia said, which has been in place since approximately 2018.

“What AFRL’s MOU with the NSF does is allow the agencies to strategically partner with and co-invest in programs and initiatives,” Vaia said. “DMREF is enabled to receive AFRL funds to co-fund grants, as well as encourage proposers to explore partnerships with federal labs to accelerate materials discovery research and development.”

From the beginning, there was one individual in particular whose efforts to connect AFRL with DMREF stood out. Senior Technologist Dr. Ruth Pachter, who currently holds Emeritus status within AFRL’s Materials and Manufacturing Directorate, has been instrumental in leading the lab’s interactions with the program, Vaia said.

“Ruth’s passion over the years working with John [Schlueter] and DMREF has changed how we think about interagency partnerships,” Vaia said. “This idea of actually bringing [the AFRL workforce] into the process … to partner with the academic community was a massive shift. She’s been doing this and continues to do this because that is her passion.”

Pachter, with her strong background in materials discovery and development and MGI-related research, has leveraged her expertise to connect members of AFRL’s S&T workforce across multiple directorates to DMREF project teams with overlapping research interests since 2018. In her Emeritus role, Pachter has sustained these efforts to facilitate the translation of materials discovery to deployment in support of DAF needs.

“From my perspective, the future of materials discovery and development, at this time, looks boundless,” Pachter said. “AFRL is not only providing a path to deployment; it’s also posing really challenging problems, which leads to fundamental research in areas that might not be envisioned otherwise. The breadth of topic areas in the collaborative projects is remarkable, ranging from structural materials and additive manufacturing to autonomous experimentation, functional materials, digital manufacturing … It is an opportune time to strengthen these collaborations.”

Still, major challenges lay ahead, particularly in taking full advantage of fast-advancing AI technologies, Pachter said.

“It is important for AFRL to be aware of AI-related opportunities and initiatives not only through government agencies, including the NSF, and academia, but also through materials and manufacturing-related AI developments in industry,” Pachter said.

Schlueter, for his part, has also been thinking ahead to the future of materials research and deployment.

“Some of the things that still need to be addressed, really, are further unification of material innovation, infrastructure, and training the next generation workforce on the power of harvesting materials data,” Schlueter said. “These are key objectives for the coming years to accelerate this progression of fundamental materials research toward deployments.”

The DMREF scope covers all materials classes and aligns with national priorities, with about 85% of DMREF proposals co-funded by multiple NSF divisions. The program focuses more on the impact of research, not the number of awards it disburses, Schlueter said.

The 2023 DMREF solicitation and submission window closed March 13, with the program ultimately awarding 37 research grants ranging from $1.5 million to $2 million, totaling approximately $75 million, over the course of four years. Typically, teams consist of 3-5 program investigators, but must have a minimum of two on each team. The biannual competition will next commence in 2025.

The sheer breadth and depth of technical knowledge and expertise embedded within the AFRL workforce strongly suggests that the number of AFRL’s partnerships with world-class academia and industry will only grow, Vaia said.

“Our scientists and engineers are externally recognized as world experts,” Vaia said. “Because of that, we are actively sought out as partners for our nations’ premier S&T programs — in this case, DMREF. The Pentagon doesn’t have to go to premier universities, for example, to get a complex question answered. They can come to AFRL — as do the folks at these leading institutions.”

The following academic institutions are currently partnering with AFRL on DMREF teams and were represented at the kickoff:

- Carnegie Mellon University

- City University of New York – Advanced Science Research Center

- City University of New York – Queens College

- Clemson University

- Florida International University

- Georgetown University

- Iowa State University

- Johns Hopkins University

- Louisiana State University

- Massachusetts Institute of Technology

- New Mexico Highlands University

- Northeastern University

- Princeton University

- Purdue University

- Rice University

- Rutgers University

- San Diego State University

- Stanford University

- State University of New York – Buffalo

- The Georgia Institute of Technology

- The Ohio State University

- University of Arizona

- University of California – Berkeley

- University of California – Irvine

- University of California – Riverside

- University of California – San Diego

- University of California – Santa Barbara

- University of Colorado – Boulder

- University of Delaware

- University of Illinois

- University of Illinois – Chicago

- University of Iowa

- University of Massachusetts – Lowell

- University of Michigan

- University of Nebraska

- University of New Hampshire

- University of Pittsburgh

- University of Texas – Austin

- University of Texas – Dallas

- University of Utah

- University of Virginia

- University of Wisconsin – Madison

About AFRL

The Air Force Research Laboratory, or AFRL, is the primary scientific research and development center for the Department of the Air Force. AFRL plays an integral role in leading the discovery, development and integration of affordable warfighting technologies for our air, space and cyberspace force. With a workforce of more than 12,500 across nine technology areas and 40 other operations across the globe, AFRL provides a diverse portfolio of science and technology ranging from fundamental to advanced research and technology development. For more information, visit www.afresearchlab.com.