AI research robots key to ‘democratizing and revolutionizing science’, AFRL researcher says

WRIGHT-PATTERSON AIR FORCE BASE, OHIO (AFRL) – Internationally acclaimed Air Force Research Laboratory, or AFRL, researcher Dr. Benji Maruyama and his team are seeking industry and academic partners to help them transition open-source autonomous experimentation software, known as Educational ARES OS, to public school classrooms across the nation to help foster the next generation of young scientists.

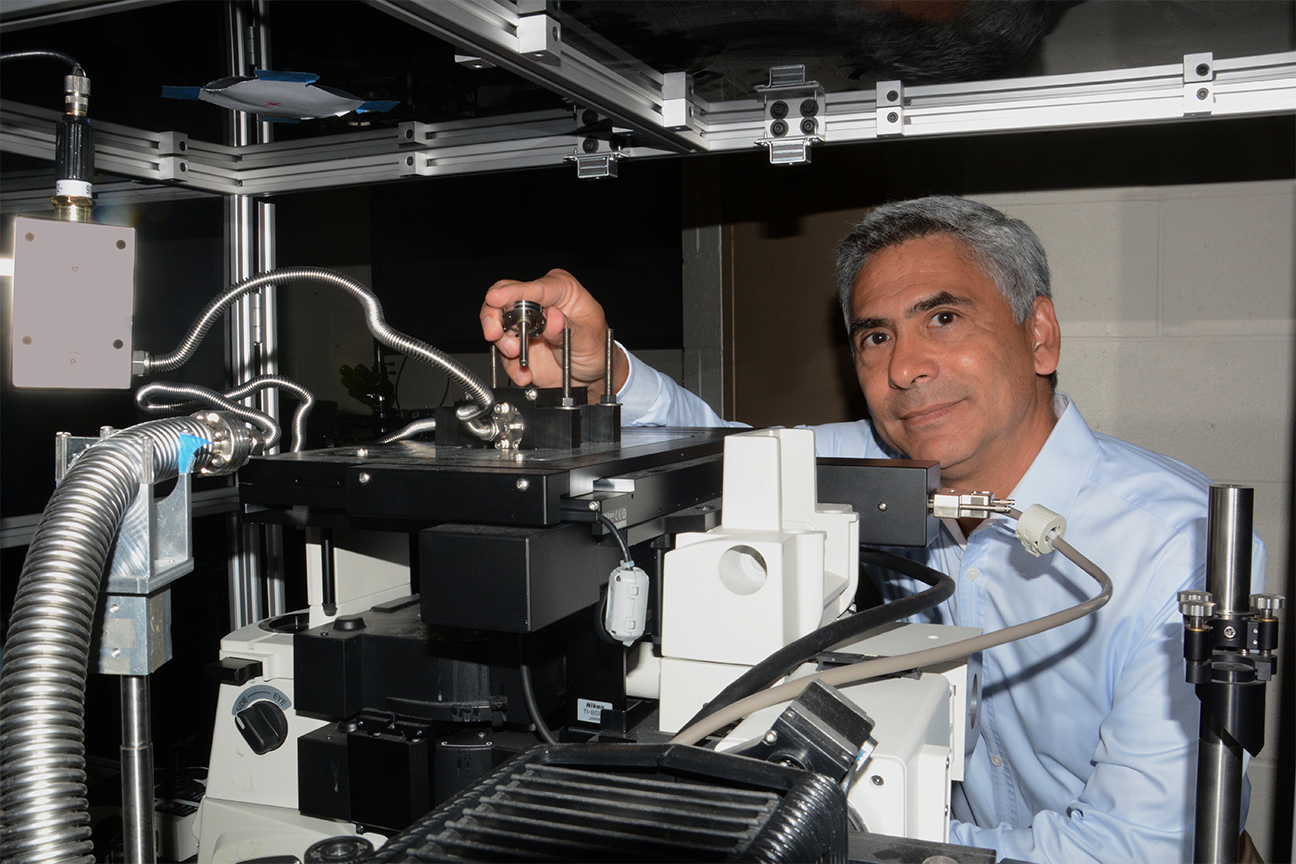

Dr. Benji Maruyama, internationally acclaimed senior materials research engineer for the Air Force Research Laboratory, or AFRL, and Materials Research Society fellow, adjusts the ARES open-source software-enabled system in its early development stages in his lab in 2017. The autonomous research system, developed by Maruyama and his AFRL team, used artificial intelligence to design, execute and analyze experiments at a faster pace than traditional scientific research methods. Maruyama and his team rolled out ARES open-source software in 2021 to overwhelmingly positive acclaim. It is currently available to the public as a free internet download. Now, Maruyama is seeking community stakeholders who will partner with him and his team to help integrate ARES into local schools for free or at extremely low cost to inspire the next generation of scientists and researchers. (U.S. Air Force photo / David Dixon)

Educational ARES OS, a self-driving research platform, combines automated robotics with artificially intelligent, or AI, algorithms to run its own experiments, record results and design and execute the next best steps to try to solve problems or find answers to research questions. It utilizes an iteration of the original ARES open-source software system that Maruyama and his team previously rolled out in 2021 to overwhelmingly positive acclaim, currently available to the public as a free Internet download.

Getting AI research robots into educators’ hands at a low cost is crucial to support AFRL’s ongoing efforts to multiply human research efforts by a thousandfold and to send the message that science is for everyone, said Maruyama, a principal materials research engineer based in AFRL’s Materials and Manufacturing Directorate.

“We need more people doing research — there are simply not enough of us,” Maruyama said. “If we don’t catch students young enough, perhaps by middle school, even, then they’ve effectively already gotten the message that science is not for them, and we really need to change that. And we need the people who are doing science in the U.S. to better represent America’s general population.”

Autonomous experimentation can effectively lower students’ barriers to entry into scientific fields by exponentially decreasing the cost of doing research, Maruyama said.

Getting artificially intelligent, or AI, research robots into educators’ hands at a low cost is crucial to support the Air Force Research Laboratory, or AFRL’s, ongoing efforts to multiply human research efforts by a thousandfold and to send the message that science is for everyone, said Dr. Benji Maruyama, a principal materials research engineer based in AFRL’s Materials and Manufacturing Directorate. “There are simply not enough of us [researchers],” Maruyama said. While AI robots grow increasingly sophisticated by the day, Maruyama said he does not fear them. AI is the key to “democratizing” science, making it more accessible to everyone as humans learn to work in tandem with evolving technology, ultimately freeing themselves from unnecessary toil and leading to greater discovery, he added. (U.S. Air Force photo illustration / Gregory Gerken)

All told, the average schoolteacher with access to Maruyama’s free open-source software on the Web and a roughly $300 budget can build their own ARES-enabled autonomous 3-D printer for individual classroom use by purchasing hardware that is widely available online. Maruyama and three colleagues recently published an open-access article describing the process of calibrating a low-cost fused deposition modeling 3-D printer system using similarly affordable components, Maruyama said.

Dr. Kristofer Reyes, an assistant professor of applied mathematics at the University of Buffalo, is currently leading efforts to kickstart a self-driving autonomous experimentation lab in its School of Engineering and Applied Sciences. The lab, projected to open in January 2024, will house one of the first educational programs to utilize Maruyama’s ARES OS software, Reyes said.

The lab and ARES will feature strongly in an undergraduate course that Reyes will teach this spring for the university’s newly minted Department of Materials Design and Innovation, titled “Experimental Design for Materials Development.” The course blends the teaching of autonomous principles related to computer science, machine learning and materials science applications, Reyes said.

“ARES was sort of the natural choice for the framework for this self-driving lab,” Reyes said. “This is how research is going to be done in the future, so we’re giving our students early access right out of the gate to become familiar with autonomous materials science and technologies.”

Among other things, Reyes said, he expects that his students will be able to utilize the new lab and ARES software to conduct metamaterial study, a process by which they can print accurate scale models of various materials and learn how to optimize their structure with respect to their individual properties.

Educational ARES software makes tackling new projects like this less intimidating, Reyes added.

“It lowers the barrier for my students and for people like me who don’t have a lot of hardware interfacing experience,” Reyes said.

Dr. Emily Fehrman Cory, principal consultant at Dayton-based Airship Consulting and former AFRL employee, is another community partner currently initiating efforts to transition Educational ARES to the classroom. Fehrman Cory first crossed paths with Maruyama when she worked as a program manager and co-lead for America Makes in AFRL’s Materials and Manufacturing Directorate in 2015.

As co-workers, Fehrman Cory and Maruyama connected over their shared interest in carbon nanotube research and commitment to STEM programming. When she kickstarted Airship Consulting two years ago, Fehrman Cory said, she reached out to Maruyama to ask how she could help to spin Educational ARES out into the wider world.

“As a transition agent, I have been trying to line up opportunities around ARES to further develop this for launch into the STEM education field,” Fehrman Cory said. “Part of this effort includes looking at how we can package [ARES] in a way that is very low cost and easy for schools to adopt. Benji is trying to take [ARES] from the Air Force into the community, and we are trying to bring the community in to meet him.”

The 2023-24 Stitt Scholar Program student cohort is pictured on the University of Dayton, or UD, campus in Dayton, Ohio, Oct. 9, 2023. UD Stitt Scholars, all of whom are multidisciplinary undergraduate students based in UD’s School of Engineering, School of Business Administration or College of Arts and Sciences, complete a paid internship experience spanning one full academic year that is typically tied to a local technology-based or -enabled entrepreneurial effort. This year, three of the Stitt Scholars selected the rollout of Educational ARES OS software, hardware and curriculum solutions into local schools for free or low-cost as their internship focus. (Courtesy photo / Michael Moulton)

Right now, Fehrman Cory’s effort to help roll out ARES STEM programming into local schools is taking the form of engagement with students and faculty at the University of Dayton, or UD. Fehrman Cory joined forces with Michael Moulton, a Faculty of Practice at UD’s School of Engineering and the Stitt Scholar Program director, to lead a team of multidisciplinary undergraduate students who were accepted into this year’s UD Stitt Scholar Program cohort. The Stitt Scholars, all of whom are students in UD’s School of Engineering, School of Business Administration or College of Arts and Sciences, will complete a paid internship experience spanning one full academic year that is typically tied to a local technology-based or -enabled entrepreneurial effort. This year, three of Moulton’s Stitt Scholars selected Educational ARES as their internship focus.

The short-term target goal, Moulton said, is for these three students to develop an Educational ARES OS-based software curriculum in support of a STEM summer camp program.

However, Moulton’s students are also operating with the long game in mind, conducting market research and using cost-benefit analysis to determine where the most reliable, cost-effective 3-D printer parts can be purchased. Ultimately, they want to find a way to affordably package a dependable hardware solution alongside ARES software and offer it to teachers as a contained kit to make it easier for them to learn how to implement the technology.

“The students working on this project have already identified some reasonable hardware solutions [to enable autonomous 3-D printing] and are now focused primarily on developing curriculum to support moving this into schools,” Moulton said. “It became pretty evident relatively early in the process that without a well-established curriculum to provide alongside the hardware and software, that integration would be very difficult.”

A significant portion of this effort requires students to visit schools within their local communities and engage with educators to determine what they want and need in their classrooms.

Raegan Rowland, a UD junior and Computer Engineering major, is one of the three Stitt Scholars who chose Educational ARES as her internship focus. Rowland said she hopes her group’s efforts will eventually lead to the development of an ARES-based curriculum that students and schools could use statewide for summer camps or mini courses that will keep students interested in learning about technology.

“The work we are doing with ARES is important because it helps kids in the Greater Dayton area experience STEM that they probably wouldn’t be able to outside of a program like this,” Rowland said.

From left: University of Dayton, or UD, undergraduate students and 2023-2024 Stitt Scholars Avery Baltrus, Anna Carollo and Raegan Rowland pose for a photo outside of their design lab on campus in Dayton, Ohio, Oct. 9, 2023. Stitt Scholars, all of whom are multidisciplinary students based in UD’s School of Engineering, School of Business Administration or College of Arts and Sciences, complete a paid internship experience spanning one full academic year that is typically tied to a local technology-based or -enabled entrepreneurial effort. This year, Baltrus, Carollo and Rowland selected the rollout of Educational ARES OS software, hardware and curriculum solutions into local schools for free or low-cost as their internship focus. (Courtesy photo / Michael Moulton)

If educators are expected to nurture students’ interest in STEM education, it is critical to give them— particularly those serving in underfunded school districts — the tools they need to teach without overburdening them, Maruyama said, and that includes curriculum.

“Teachers are already saddled with massive workloads, and we know there isn’t always time to do something extra like designing and implementing their own autonomous 3-D printing curriculum,” Maruyama noted. “In the case of Educational ARES, we are hoping to deliver not only the robot, but also a full curriculum that’s written out to state standards, to lower the barriers to entry for teachers to implement autonomous experimentation in their own classrooms.”

Researchers can spend hours printing failed parts in a lab before finding the optimal settings needed to create a given experimental material, according to AFRL’s original 2021 press release. The pairing of Educational ARES and 3-D printing can result in reduced margin of error and fewer wasted materials, as the robot can automatically suggest the best way to print a needed material the first time around.

Additionally, access to low-cost autonomous 3-D-printing capabilities can be pivotal across multiple classroom disciplines, Maruyama said, as the ability to 3-D print physical materials in the classroom can help hands-on learners to better absorb information. In a human anatomy class, for example, a student might be asked to 3-D print replicas of bones and organs to envision how academic terminology relates to the human body.

“The goal of autonomous experimentation is not to replace humans, but to augment them.”

~ Dr. Benji Maruyama, Air Force Research Laboratory principal materials research engineer

And while artificially intelligent robots grow increasingly sophisticated by the day, Maruyama, for his part, said he does not fear them. Instead, he sees AI as the key to “democratizing” science, making it more accessible to everyone as humans learn to work in tandem with evolving technology, ultimately freeing themselves from unnecessary toil and leading to greater discovery.

“The goal of autonomous experimentation is not to replace humans, but to augment them,” Maruyama said. “The next generation of scientists and engineers, these young people, the young graduate students who are doing this work — we are losing them because we are failing to give them the tools to leverage what they want to do. Imagine that you’re a farmer and somebody points you to a horse and plow and says: ‘Go till that field.’ You’re going to say: ‘No, that’s crazy, I want the combine harvester.’ But that’s essentially what our young researchers are going through right now. They go into the lab, they pipette and polish samples, they turn switches on and off. And these are things that can and should be automated.”

Up-and-coming students and young researchers are voting with their feet, Maruyama said, choosing not to go into research fields after completing their graduate coursework when faced with the tedium of rote experimentation and data collection in their labs.

“They’re going elsewhere,” Maruyama noted. “They’re choosing to go work in finance or consulting or software development instead, and not because they don’t like science — they just don’t enjoy the tedious aspects of science. We’re making them do work that’s better done by robots.”

In the spring of 2023, Maruyama was named a Materials Research Society, or MRS, fellow, not only for his extensive efforts to create and promote free, open-source AI software, but also to develop carbon nanotubes — research that bears promising implications for reducing the effects of climate change — and extensive diversity, equity and inclusion work. The MRS, currently 13,000 strong, has named less than 2% of its current members as fellows.

Dr. Sergei Kalinin, professor of Materials Science and Engineering at the University of Tennessee at Knoxville, nominated Maruyama, a longtime friend and colleague, as an MRS fellow. While Maruyama is currently one of many scientists internationally who network tirelessly to promote AI efforts, he was one of the very first to pioneer his vision for a future in which humans would work alongside AI, Kalinin said.

“At varying inflection points throughout history, you can point to these individual scientists who have laid the foundation, sort of ignited these moments of transition,” Kalinin said. “Benji is one of very few people who had this very specific vision [about the future of artificial intelligence and autonomous experimentation] and was in the position to implement this vision, and that vision has provided the foundation for future efforts. Benji was the person who showed us, made the scientific community believe, that the use of machine learning and automated experimentation could come together and make an impact, even in the materials world.”

“What you need to have, in addition to great ideas, are persistence, perseverance and the right environment in which to make those ideas work, to make them ring. In Benji’s case, he clearly was the person in the right place at the right time with the right ideas, and that has made all the difference.”

~ Dr. Sergei Kalinin, University of Tennessee-Knoxville professor of Materials Science and Engineering

Ideas by themselves are simply not enough, Kalinin said, to drive technological efforts of this magnitude.

“What you need to have, in addition to great ideas, are persistence, perseverance and the right environment in which to make those ideas work, to make them ring,” Kalinin added. “In Benji’s case, he clearly was the person in the right place at the right time with the right ideas, and that has made all the difference.”

Maruyama is also exploring how to utilize artificial intelligence to reduce the effects of climate change; his research efforts connected to carbon nanotube development have established him as one of the world’s leading climate-conscious researchers. According to a September 2021 article published for Forbes, Maruyama and his team conceptualized ARES OS originally as a way to speed up carbon nanotube research, as the slow pace of discovery through lab experiments hindered his work.

“Carbon nanotubes are these wonderful materials that are super stiff, super strong, lightweight, electrically and thermally conductive,” Maruyama explained. “They have all these great properties that we can harness to make all kinds of things that we need, more sustainably — but, we don’t have the science yet to make them at scale, meaning at millions of tons per year. If we can do it at scale, we might just be able to reduce global CO2 emissions by, say, 20% to 40%, which allows us to meet 2050 goals.”

Dr. Benji Maruyama, principal materials research engineer based in the Air Force Research Laboratory, or AFRL’s, Materials and Manufacturing Directorate, displays a model of a carbon nanotube structure in his research lab in 2016. Carbon nanotubes are of great interest to materials scientists due to their strong, lightweight structure, ability to conduct heat and electricity better than many other materials, and promising implications for reducing the effects of climate change. In the spring of 2023, Maruyama was named a Materials Research Society, or MRS, fellow largely due to his extensive efforts to promote and develop carbon nanotube research. The MRS, currently 13,000 strong, has named less than 2% of its current members as fellows. “Carbon nanotubes are these wonderful materials that are super stiff, super strong, lightweight, electrically and thermally conductive,” Maruyama explained. “They have all these great properties that we can harness to make all kinds of things that we need, more sustainably — but, we don’t have the science yet to make them at scale, meaning at millions of tons per year. If we can do it at scale, we might just be able to reduce global CO2 emissions by, say, 20% to 40%, which allows us to meet 2050 goals.” (U.S. Air Force photo / Marisa Novobilski)

The unique properties of carbon nanotubes, which have a drastically reduced carbon footprint in comparison to other materials, make them an excellent potential swap for their less sustainable counterparts, including plastic, steel, and concrete.

“Obviously, we know that carbon dioxide pollutes the atmosphere and a lot of that comes from fossil fuels, especially natural gas,” Maruyama said. “Natural gas is mainly just carbon and hydrogen, and more energy is found in the hydrogen. Using a chemical reaction called pyrolysis, essentially heating up the natural gas and methane, we can separate the hydrogen and use that as a clean energy source. We can use it to generate electric power, we can use it for fuel-cell powered vehicles. It can power all kinds of things cleanly and efficiently. The carbon from the methane is sequestered as carbon nanotubes instead of being released into the atmosphere as carbon dioxide.”

However, materials such as plastic, steel and concrete are currently much cheaper to make at scale, and research has a long way to go in determining how to make carbon nanotube production affordable.

That is where artificial intelligence and autonomous research software come into play, Maruyama said, as artificially intelligent tools can lessen scientists’ burden and toil and come up with answers to tough research questions much faster than humans can by themselves.

“With our original ARES system robot, we went from being able to do one experiment a day to one experiment in five minutes, roughly 100 experiments a day,” Maruyama said. “Additionally, the AI algorithm in ARES is doing all of that cognitive labor of determining the next best steps, taking that burden off of the researcher.”

Dr. Benjamin Leever, principal general engineer and Maruyama’s branch chief in AFRL’s Materials and Manufacturing Directorate, said that it is a credit to AFRL to employ a researcher of Maruyama’s caliber.

“Benji is an exceptional researcher who is incredibly passionate about what he does,” Leever said. “For AFRL to have access to a scientist with the kind of publication and presentation record he has, with that kind of reputation amongst members of the scientific community — it’s just phenomenal. We are very, very lucky.”

Maruyama’s personal commitment to recruiting future researchers is particularly notable, Leever said.

“That’s truly the hallmark of a talented researcher, to be someone who not only makes these incredibly significant contributions to science, but who can also see the bigger picture and understand how those contributions are going to impact other fields,” Leever said. “Benji is out there talking to other research pioneers to drive a national strategy for autonomous research. He’s an ambassador for this field and getting lots of people, young and old, excited about science and inspiring people to consider that career path. And that’s unique.”

“The computer doesn’t know what’s right, what’s good. That’s the human’s job, to provide that creativity, that insight, that oversight… The point of autonomy is not to replace the human. It’s about giving humans the tools and the ability to team up with technology; it’s about working in concert. Ultimately, you’re the one who knows what’s truly right, because you’re the human.”

~ Dr. Benji Maruyama, Air Force Research Laboratory principal materials research engineer

At the end of the day, Maruyama says, it is safe to assume that there will always be a human in the loop when it comes to working alongside machines.

“The computer doesn’t know what’s right, what’s good,” Maruyama said. “That’s the human’s job, to provide that creativity, that insight, that oversight. You know, a lot of people right now are concerned about things like ChatGPT, or artificially enhanced photographs. But when you look closely, what you see is that this kind of technology simply doesn’t replace people. It does a reasonable job, maybe, of accomplishing specific tasks, but it’s always kind of flat. The writing is flat — the art is flat — and in science, it can’t really reason. If you’re looking to find something in the data set, then AI is really, really good at finding it. But the creativity just isn’t there.”

Ideally, Maruyama said, he’d like to see a world in which humans can embrace a partnership with AI instead of working against it.

“You know, especially in the beginning, I got a lot of, ‘Hey, Benji, what are you doing?’” Maruyama said. “People got, and still get, really upset and anxious about AI. But the point of autonomy is not to replace the human. It’s about giving humans the tools and the ability to team up with technology; it’s about working in concert. Ultimately, you’re the one who knows what’s truly right, because you’re the human.”

About AFRL

The Air Force Research Laboratory, or AFRL, is the primary scientific research and development center for the Department of the Air Force. AFRL plays an integral role in leading the discovery, development and integration of affordable warfighting technologies for our air, space and cyberspace force. With a workforce of more than 12,500 across nine technology areas and 40 other operations across the globe, AFRL provides a diverse portfolio of science and technology ranging from fundamental to advanced research and technology development. For more information, visit www.afresearchlab.com.