New DAF software factory aims to digitally transform AFRL

WRIGHT-PATTERSON AIR FORCE BASE, Ohio (AFRL) – The chief software officer for the Air Force recently designated Hangar 18 as a Department of the Air Force software factory.

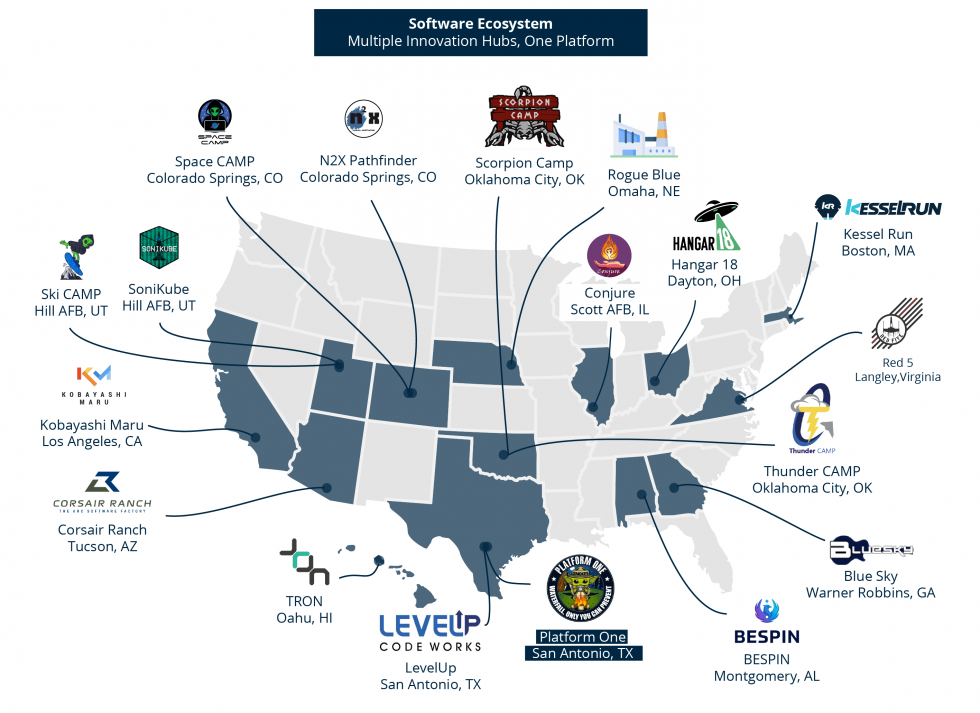

Hangar 18 joins 16 other DAF software factories—including the first, Kessel Run—that have sprung up across the nation since the Air Force began its digital transformation efforts in 2017. These efforts were initially driven by the release of the Air Force Science and Technology Strategy for 2030, released in 2017, and then influenced by the digital engineering initiative laid out by Dr. Will Roper, former assistant secretary of the Air Force for acquisition, technology and logistics.

Matthew Jacobsen, director of Hangar 18, cited Roper’s articles “There is no spoon” and “Bending the spoon” as significant in the formation of the software factories and Hangar 18’s charter.

“If you look at that trifecta that he proposes, [the Air Force has] to own all aspects of the data lifecycle,” Jacobsen said. “[The Air Force has] to own the data—it’s not enough for us to just have unlimited rights to the data; that’s not sufficient. We have to own the data, the processes and the stack; so, we need better control of the technology that houses data. And the second thing we need is a focus on agile practices; we need to do a much better job of employing agile methodologies in our engineering practices. We have to move fast and be adaptive.”

Hangar 18 is a cooperation of digital teams and assets at Wright-Patterson that the DAF, the Air Force Institute of Technology and the Air Force Research Laboratory are coordinating. The cooperation first began after software engineering teams and data engineering teams from AFIT’s Cybersecurity Technical Center of Excellence and AFRL’s Materials and Manufacturing Directorate were brought together, which led to the realization that all of their collective experience could create a joint effort that benefits programs such as Low-Cost Attritable Systems, Jacobsen said.

“We have multiple tools and environments in our portfolio, we have multiple areas of specialty between our teams, and, ultimately, you can see that our mission is to use these assets to solve real problems and create pathways to success for teams struggling in the data and software space. These pathways deliver solutions on the Air Force networks that are focused primarily on digital engineering use cases,” said Jacobsen.

Upon looking at the map of the existing Air Force software factories, the team decided, “Why isn’t Dayton represented? Let’s get Ohio on the map,” Jacobsen recalled.

And so, they drafted a memorandum of understanding between AFIT and AFRL and briefed their respective leadership, explaining what they’re trying to do and the stakeholders they’re looking to serve. After receiving approval, they presented a charter to then Air Force Chief Software Officer Nick Chaillan, asking to be recognized as a formal software factory, and were given the green light.

“The factories that you see on [the] map really are [Chaillan’s] legacy, as are Platform One and Cloud One,” Jacobsen said. “I come from a background in commercial software engineering. That’s where I cut my teeth, and the rate of change inside the fence can be very frustrating by comparison. And not just the rate of change but the barriers—the compliance barriers. You have innovators, and you have compliers; it’s difficult to reconcile those two. We have to make sure we’re not being cavalier with our data protection, but at the same time, we have to increase our velocity; we just do.”

Chaillan abruptly left his role as Chief Software Officer Sept. 2, 2021, citing disappointment with Air Force software development.

“I think that Mr. Chaillan saw a lot of potential in the cloud, DevSecOps and Agile space, and, ultimately, we see his departure as, what will hopefully be, a forcing function for Air Force leadership and DOD leadership to change how they mean to address this problem.”

One challenge area, Jacobsen said, is that many data and software projects are led by and consist of expert scientists and engineers who admittedly don’t sufficiently understand the data and software domain, which could eventually cause programs to be overly time-consuming, expensive and, in some cases, not successful.

“So we said, ‘Let’s move fast to start creating and delivering tools and capabilities.’ There’s a big push for digital engineering in the Air Force. That’s a very good thing, but there are some foundational elements that are needed. You need robust environments for technology delivery, and you need pipelines for the data to be generated, to ensure that it is adequately curated, discoverable and reusable. You also need what we refer to as DevSecOps and Agile capabilities that help drive higher rates of success on digital initiatives.”

His team and the AFIT team had already been delivering software and data capabilities for a long time, he said, but the Hangar 18 coalition gives both sides broader access to more contract vehicles and funding opportunities to stand up new projects. Jacobsen claimed that they have saved the LCAS project $1.5 million to date and will save LCAS another $2 million going forward because they are implementing tools and methods for the Air Force to own its own data and not rely on a third party to contract out.

The speed with which Hangar 18 can deliver capabilities has also seen rapid acceleration due to strategic technology partnerships. They’ve enabled hundreds of terabytes of data to move out of the lab into networked ecosystems such as Google Cloud through the work that they’ve done.

“By creating a path forward for integrating all of these data-rich isolated environments, we are accelerating the delivery of real capabilities for these communities,” Jacobsen said.

He explained that Agile and DevSecOps software practices that leverage modern tools and frameworks incorporate security and infrastructure operations for automated and continuous delivery. In addition, the partnership with AFIT allows access to its faculty and the ability to provide training, such as workshops, and outreach to the current and future workforce. Hangar 18 also serves as a communication hub to avoid replication in software efforts and redundant spending. They recently brought together engineers from around the Wright-Patterson community to share perspectives at a DevSecOps collider event.

“One of the things Hangar 18 can do for digital acquisition and engineering, as well as digital transformation, is serve as an essential communication hub: who’s doing what and where? And what things are working; what things are not working? How do we better integrate our key digital assets? How do we move beyond outdated processes?”

“So, what we’re doing is bringing the types of tools and methods that commercial software companies implement to be successful, and we’re delivering those inside the fence. Benchmarking ourselves against the best of the best can be difficult and frustrating, but it’s an important step toward progress and ensures long-term warfighter capability. Hangar 18 is ready to tackle your software and data projects. We can build capabilities for you, we can come alongside and be a key advisor, or we can educate and train your team.

Visit https://software.af.mil/softwarefactory/hangar-18/ for more information or to contact Hangar 18.

The Hangar 18 software factory aims to deliver key digital capabilities to the Wright-Patterson acquisition and engineering community as a timely, low-risk investment. (Courtesy Illustration)

The Department of the Air Force now boasts a software ecosystem of 17 innovation hubs and software factories under one platform across the United States. (Courtesy Illustration)