HYDROCARBON BOOST (HCB) TECHNOLOGY DEVELOPMENT PROGRAM

What is a Preburner?

A preburner is the heart of a staged combustion liquid rocket engine, harnessing the energy to power the other engine subsystems. The Air Force Research Laboratory successfully completed testing of a next-generation rocket preburner as a part of the HydroCarbon Boost (HCB) program.

The HCB preburner was highly instrumented to assess performance and develop a physics-based understanding of Oxygen-Rich Staged Combustion (ORSC) cycle engine technologies. The HCB preburner design and test data is available to the entire U.S. rocket industry for current and future domestic engine developments.

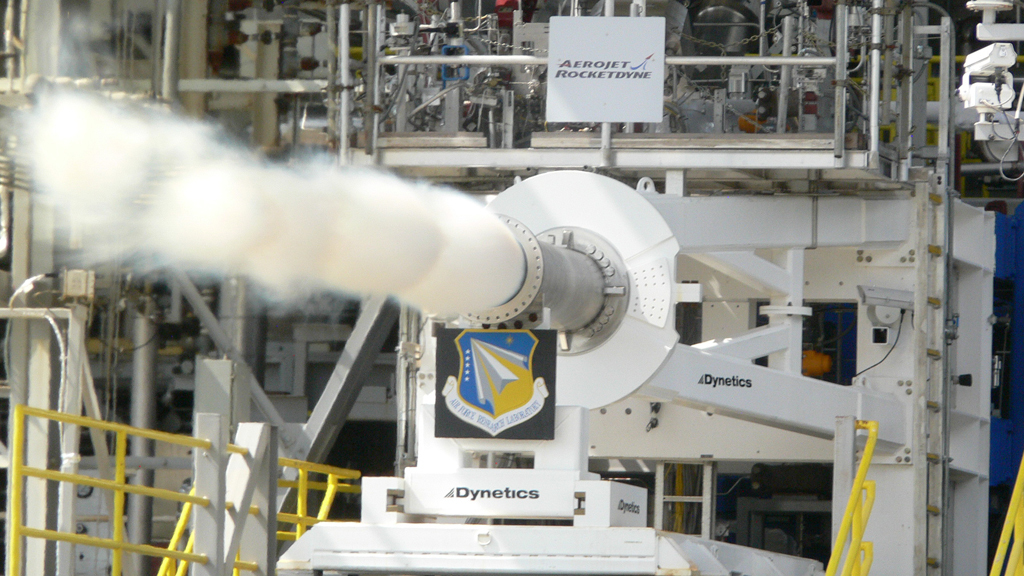

The HCB program, along with Aerojet Rocketdyne and supported by the U.S. Air Force Space and Missile Systems Center, has completed preburner testing at NASA Stennis Space Center facilities. This achievement follows successful testing of the HCB sub-scale preburner in 2016 at the AFRL Rocket Lab at Edwards Air Force Base in California.

The HCB preburner uses liquid oxygen (LOX) and kerosene fuel, which has advantages for the combination of high-performance and low weight launch systems.

Why is It important?

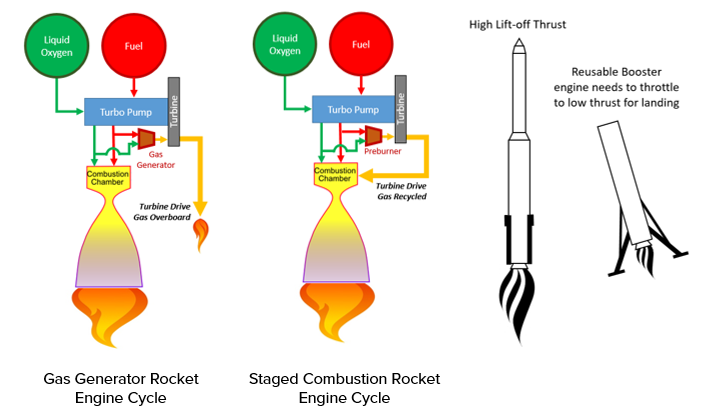

Not only has the HCB preburner operated at higher pressures than any other U.S. rocket combustor, but it was designed for extensive reusability and deep throttling. The HCB preburner lays the foundation for future reusable systems with minimal maintenance between flights, surpassing achievements in reusability under the Space Shuttle main engine program. Multiple rocket propulsion technology concepts exist for designing launch vehicles.

HydroCarbon Boost Preburner test. NASA Stennis Space Center (2019)

Looking to the future, staged combustion rocket engines with hydrocarbon fuels offer advantages for launch vehicle performance and reusability compared to heritage U.S. rocket systems. These benefits translate to increased payload mass to orbit at lower cost.

Russia invested in ORSC technologies for many decades, and currently has multiple ORSC rocket engines, such as the RD-180 used on the U.S. Atlas V. The U.S. staged combustion rocket engine technology with hydrocarbon fuels has advanced quickly over the past five years, and U.S. industry developed multiple engine concepts, such as the SpaceX Raptor engine and the Blue Origin BE-4.

A key objective of the HCB program is to mature technology solutions for reusable rocket engine systems, with high performance for increased mass to orbit, long life between engine overhaul for reliability and affordability, and highly throttleable in thrust level to land reusable boosters.

To this end, the HCB program is establishing a physics-based understanding of ORSC technologies with test data, demonstrating unique design features, and advancing state-of-the-art rocket engine design tools. These products are available to the entire U.S. launch industry to resolve key technical challenges, such as combustion stability and engine survivability in the high-pressure oxygen environment. Ultimately, this Air Force investment will enhance U.S. launch capabilities through increased reusability, performance, and affordability.

How Does It Work?

The preburner component is a critical technical challenge for staged combustion rocket engine systems. Staged combustion engine cycles achieve high efficiency by using all available propellants to generate thrust, which differs from other engine cycles that dump a fraction of the propellant overboard after powering the turbomachinery, such as on the F-1 engine used on the Saturn V rocket or the RS-68 engine used on the Delta IV launch vehicle.

BENEFITS:

Improved performance and reusability for ORSC rocket engines.

- High performance enables lower cost to orbit.

- Oxygen-rich combustion (ORSC) is cleaner burning to enable faster engine servicing and rapid re-launch.

- Unique HCB designed for long life to enable more launches between servicing and overhaul.

Created a U.S. technology base for ORSC engine systems.

- Russian RD-180 booster engines are used on the Atlas V and Antares launch vehicles

- HCB design and test data is available to entire U.S. industrial base.

- HCB redefines state-of-the-art beyond RD-180 capabilities.

In staged combustion engine systems, higher pressure of the drive propellant gas in the preburner increases the overall engine efficiency. However, the highly reactive oxygen environment combined with the high-pressure and hot temperature of combustion in a preburner guarantees that most metals will combust or melt. The challenge is in finding a material able to survive this extreme environment, or trade overall efficiency by lowering the drive pressure to utilize more common materials.

Summary

The AFRL HCB program completed testing of a state-of-the-art rocket engine preburner at NASA Stennis Space Center, with contractor Aerojet Rocketdyne and with support of the U.S. Air Force Space and Missile Systems Center. The HCB preburner is the highest-pressure full-scale U.S. rocket engine component ever tested. It is designed to demonstrate oxygen-rich staged combustion technologies for higher performance and reusable rocket engine systems, and will expand the design space for future domestic flight engines.